PRECISE CONTROL

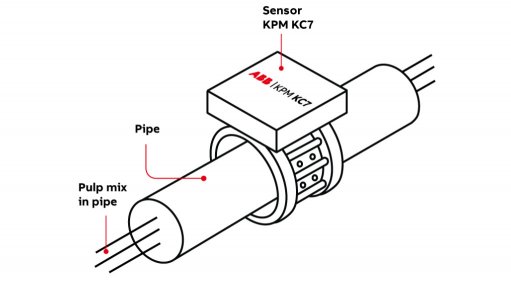

The KPM KC7 employs microwave true-phase technology, which has been proven to provide precise total consistency measurement of mixed pulps, different quality pulps and pulps with filters, regardless of flow rate for superior process control

Photo by: ABB

Technology leader in electrification and automation ABB has completed the delivery of KPM KC7 microwave consistency sensors to a new paper mill in Pelasgia, Greece, owned by integrated paper and packaging company Unipak Hellas Central SA.

This is the first time that a customer has chosen to use high-quality microwave-only sensors, rather than a combination of different measurement technologies, throughout an entire facility.

KPM KC7 employs microwave true-phase technology, which has proven to provide precise total consistency measurement of mixed pulps, different quality pulps and pulps with fillers, regardless of flow rate, for “superior” process control.

“Mills can achieve the most representative, accurate, reliable measurement unaffected by process variables or obstructions. Additionally, the transmitter has no moving parts enabling high equipment uptime and minimum maintenance,” the company states.

The inline, dual-plate design is equipped with an optional retractable temperature sensor for hard processes. The flow-through model fits pipes of up to 16 inches in diameter for the most representative results.

The KPM KC7 solution is suitable for the blend/mixing chest, machine chest, recycled pulps and pulps with changing quality.

“By choosing to install ABB’s microwave consistency transmitters, Unipak Hellas is further increasing efficiency,” states Unipak Hellas division process improvement manager Jihad Hasrouni.

He explains that it is a part of the company’s drive to boost production capacity of recycled corrugated case material, such as test liner and recycled fluting grades at its mill in Pelasgia.

ABB area sales manager Erik Teunissen notes that the customer had brought the mill online in 2023, with the company looking forward to the customer’s team realising the benefits of solving all consistency problems with one kind of sensor.

He expressed that ABB was pleased to work with Unipak Hellas to deliver a complete one-order solution encompassing the delivery of the sensors along with technical support.