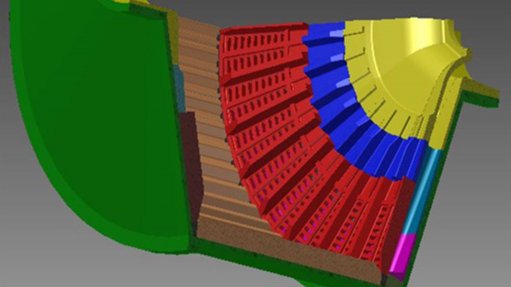

PULP LIFTERS Pulp lifters can facilitate better movement of milled materials towards the discharge end of the mill

Vast improvements can be achieved on large mills with the addition of customised pulp lifters, which facilitate better movement of milled materials towards the discharge end, says mine processing components manufacturer Tega Industries South Africa.

The company has invested heavily in discrete element modelling and computation fluid dynamics systems that enable it to assist mines to introduce customised components, which dramatically improve performance and durability of their materials handling and processing equipment.

Pulp lifters play an important role in large mills where the veins are used to direct and transport processed slurries to the discharge end in a fast and efficient manner. However, not all pulp lifters are created equal and Tega Industries has introduced new technologies that make it possible to conduct accurate studies and gather data on the movement of materials inside the mills to help custom-design pulp lifters, which helps address carryover and materials flowback, which traditionally reduces the efficiency of mills.

Free-Flowing Systems

Tega Industries marketing and business development manager Vishal Gautam says the pump lifter sits at the discharge end of the mill behind the grate that is used to separate classified (fine milled) materials from the larger particles.

These classified materials are prone to compaction or blocking and pulp lifters are traditionally used to separate and funnel materials to the discharge.

“However, the pulp lifters themselves may not work as efficiently as they should and carry over materials into the next cycle. This has the effect of reducing throughput and limiting production. Likewise, flowback of materials over the veins of an inefficient pulp lifter equally robs a good mill of a considerable amount of its potential output,” he says.

Gautam adds that, through Tega Industries’ modelling processes and high-tech manufacturing facilities in Vulcania, Gauteng, the company is able to manufacture lifters that address any of these limiting factors and, in addition, will take into account wear factors and other issues that may improve the performance and overall life span of a mill.

Gautam adds that a number of factors are used to determine the type of lifter required, such as grate designs, particle size distribution, mill diameters and revolutions per minute, which ultimately define the required geometry, height and number of veins on a lifter.

Material, viscosity and other technical factors will also determine the shape of the lifter and materials used to manufacture it. Once that has been determined, the pulp lifter will ensure that the mill operates at ultimate efficiency over the required life span of the mill.

Gautam says a mine’s output is directly determined by the throughput of its mills. By enhancing and increasing the reliability of mills with the aid of specially designed pulp lifters, mines can make quick and easy improvements to their processes, which will have a direct positive impact on earnings and profitability.