RELIABLE A conveyor drive system must allow for easy lubrication to operate at different speeds without the need for additional lubrication systems

A conveyor drive system functions optimally when it is designed to balance thermal and mechanical ratings with bearing life, says engineering and gearing innovation company David Brown Gear new build manager Louis van den Bergh.

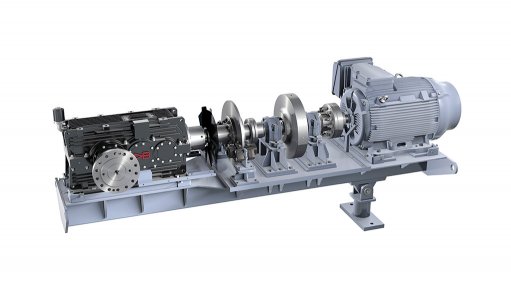

David Brown, whose head office is based in the UK, designs and manufactures its CX series of bevel helical gear units at its South African branch in Benoni, Ekurhuleni. The facility is the company’s mining-gear centre of excellence and manufactures conveyor drives, mill drives, fabricated girth gears and cast girth gears for the worldwide David Brown group. The facility is also equipped with a gearbox service centre, including repairs and upgrades, for customers across Africa.

Van den Bergh tells Mining Weekly that the CX series of bevel helical gear units, which was launched in 2011, is suitable for mining operations in Africa, as its thermal efficiency allows for operation in high temperatures.

He adds that David Brown can optimise the gear geometry for reduced transmission noise and increased bearing life through a combination of pressure angles, helix angles, profile corrections and advanced lead modifications.

“Traditionally, units are often limited thermally, rather than mechanically, resulting in their being used with very high mechanical service factors. CX thermal ratings are optimised to such an extent that the thermal limiting effect does not result in such high ‘overselected’ mechanical ratings. This has a direct effect on the overall allowable power-to-weight ratio,” explains Van den Bergh.

The CX series is designed for applications in coal, iron-ore, cement, copper, gold, silver and platinum, he says, adding that the gear units combine the adaptability of a custom- engineered solution with the price and lead time of standard gear units.

Van den Bergh states that the company’s conveyor drives have been in operation for decades, “with some even surviving hurricanes and sweltering 45 °C heat, virtually maintenance free”.

Other features of the CX series include a finned design with axial fan and a flippable design with removable feet.

“The gear case and fan design delivers up to 20% increased thermal capacity and reduces the need for additional cooling equipment.

“The CX series benefits from a ‘design for manufacture’ philosophy, which means optimum product performance and reliability, with minimum spares required,” concludes Van den Bergh.