Master Lock’s products will be on display in Hall 6 of the Electra Mining Africa exhibition

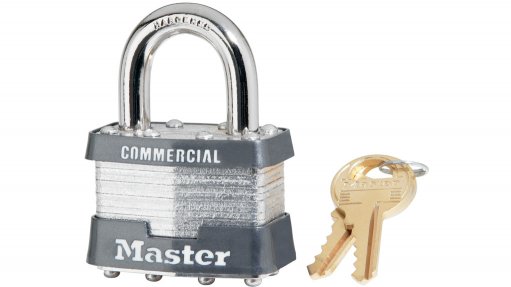

The lockout and tagout devices that international group Master Lock manufactures, and South Africa-based IB McIntyre & Co sells, are preventing “thousands of accidents” every year.

IB McIntyre & Co operations director Robert Pullinger explains that the lockout and tagout procedure protects employees from risks caused by all forms of energy. “When used properly with a well-planned lockout process, the safety padlock will ensure that workers will not inadvertently energise equipment, while someone else is working on it.”

Master Lock provides sophisticated keyed systems for improved security – each employee carries a unique key for their padlock that no other key can open. The company currently offers over one-million unique keys.

Master Lock also has a wide range of lockout and tagout labels to identify the operator by name, task and the duration of the operation. The labels are available in many different designs to suit all applications and are heat and chemical resistant.

The Master Lock lockout and tagout device will be on display at Electra Mining Africa. Other products on show will focus on security, which Pullinger points out is a relevant topic of discussion in South Africa, where crime is an issue.

Visitors to Stand C1 in Hall 6 will see how Master Lock’s products provide peace of mind when it comes to the threat of unauthorised key duplication and lock bumping.

The global padlock manufacturer provides a unique dedicated system based on a specific keying system to eliminate the risk of unauthorised duplication. Pullinger says the Edge Key Control System from Master Lock ensures that keys can only be duplicated with proper authorisation by certified Master Lock dealers. This is accomplished with the addition of an innovative, proprietary, added cylinder locking feature that creates an exclusive range of cut keys that are available with every Edge system.

He explains that the new system has a secondary locking mechanism in the form of two ball bearings on each side of the keyway. Keys have a dimple cut on each side of the new actual key section. The ball bearings are required to align with a slot in the shell before the key can be removed and that means that the service holes on the bottom of the shell cannot be used for rekeying as with standard cylinders.

To deal with the threat of lock bumping, which is a type of lock picking technique using a specially crafted bump key, Master Lock has developed an exclusive patent-pending bump stop that prevents the transfer of force from the bump key to the pins and blocks rotation of the cylinder.

“With a reverse rake tapered driver pin, high performance spring and precision tolerance chamber, bump stop is four times stronger than the toughest proposed anti-bump industry standard.”

Hall 6 Stand C1