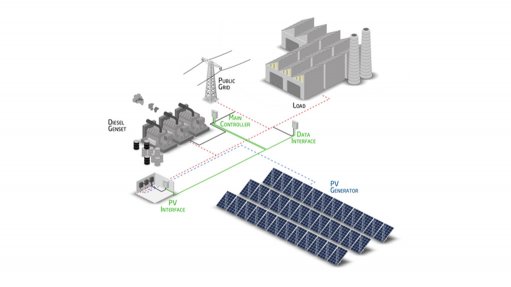

HYBRID SOLAR-DIESEL POWER PLANT. Photovoltaic systems are easily integrated into existing diesel generated power supply sytems

Energy solutions provider Cronimet Mining Power Solutions’ first megawatt-scale, solar-diesel hybrid power plant, at the Cronimet Chrome South Africa Thabazimbi openpit chromium mine, in Limpopo, has significantly reduced the mine’s diesel consumption, allowing for more effective energy management and reduced operational costs, according to sustainable energy consultant Dr Thomas Hillig.

The 1 MW photovoltaic (PV) plant, which was incorporated with the original diesel genset in November 2012, after which a 500 KVA grid connection was added in 2014, is the first of its kind in the international mining sector, says Hillig.

The PV system was integrated into the mine’s diesel system by installing PV hybrid controllers, which are essentially several inverters that interact with a programmable logic controller (PLC).

The PLC enables the diesel genset to offset any losses brought about by changes in the weather, such as cloudy conditions.

The PV hybrid controllers basically act as an interface between the PV installation, the diesel gensets and the loads, Hillig says, adding that the controllers interpret the PV installation as a flexible negative load.

It is important that the gensets provide enough spinning reserve to cover sudden losses from the PV plant at any time, for example, during cloudy conditions, he notes.

Hillig believes that adding the grid connection was a sound investment decision because, in South Africa, “electricity costs are among the lowest in the world, but, simultaneously, [State-owned power utility] Eskom has large losses – that means that grid electricity is actually economical”.

Since the mine’s solar power use has no direct costs, the grid connection enables the company to save on operational costs over the remaining life of the mine, as diesel costs are far more expensive than the cost of electricity supplied by the national grid. Thus, the savings on diesel negate the initial cost of connection, he explains.

A September 2015 report, titled ‘Solar projects, energy efficiency and load shifting for an optimised energy management in the mining industry’, produced by Hillig, Cronimet engineer Dr Georg Wirth and Sabrina Steinhauser, states that the Thabazimbi mine’s diesel consumption decreased by 450 000 ℓ/y since the implementation of the PV plant, which, in turn, reduced carbon dioxide emissions by about 1 200 t/y.

Hillig says that, in the mining industry, the combination of diesel gensets and solar power is rather common, though he notes that the use of PV-diesel hybrids is relatively new. However, he adds that, outside of mining, there have been PV-diesel hybrid installations, with some dating back 15 years.

Solar Thermal and PV

Solar thermal electric-energy generation concentrates sunlight to create heat, which warms a fluid that runs a heat engine that subsequently turns a generator to produce electricity.

Solar power generation is particularly attractive because heat can be stored by day and converted into electricity at night.

Alternatively, PV systems directly convert the sunlight into electricity using solar panels that are only effective during daylight because – with current technology – the process of storing electricity is neither particularly effi- cient nor cost effective.

Regardless, Hillig believes that the idea for PV-diesel hybrid plants came about because “electricity generation based on diesel has always been quite expensive, so special efforts had to be undertaken to reduce . . . diesel consumption”.

The report states that, typically, once PV hybrids had been introduced, supply costs were reduced by 25% to 30%, and that, in very remote locations, with elevated diesel prices, the reductions could amount to more than 70%.

It also notes that, from a demand perspective, implementing energy efficiency measures and load shifting could have substantial effects on a mine’s electricity consumption.

Hillig and his associates note that energy efficiency can account for a 5% to 20% reduction in electricity consumption and that implementing load shifting can reduce costs by 5% to 10%.

Avoided or shifted energy consumption ensures that the integrated solution decreases the amount of capital expenditure needed for upgrading or maintaining the existing diesel gensets.

“ . . . [T]he customers profit by spending less,” says Cronimet Mining Power Solutions MD Rollie Armstrong.

The report further states that energy efficiency measures and load shifting require a thorough knowledge of mining processes, and that it is obvious that the simultaneous optimisation of demand and supply side are much more complex than the construction of a traditional PV power plant.

Further, Hillig believes that a prerequisite for finding the best solution is combining skills from mining and solar energy.

Hillig notes that, while many developing African countries initially disregarded this PV Hybrid solution, partly owing to a lack of external financing, this is no longer the case.

He believes that, eventually, it might be possible for a mine to run entirely on renewable energy, although this would be more likely during the day, he adds. “To have a 24-hour [operation], powered by solar or wind, you need plenty of storage capacity, which is currently rather expensive.”

However, while storage prices are expected to fall, Hillig concludes that “[the mining industry is] still far from 24-hour operations that are economical”.