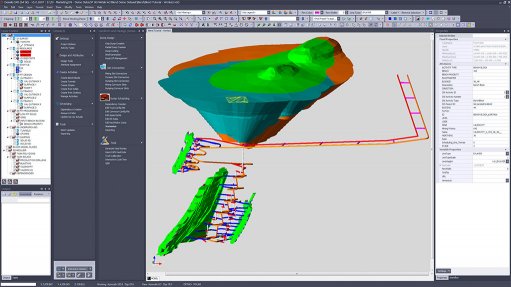

DESIGNING FOR EFFICIENCY Deswik enables mines and exploration projects to make design changes and update their schedules immediately to effectively deal with operational challenges

Owing to ongoing commodity price pressure, many larger feasibility studies have been replaced by operational improvement and smaller opportunity assessment studies over the past few months, global consulting and technology company Deswik has found.

Deswik consulting manager John Buffington tells Mining Weekly that active mining feasibility studies and mine constructions are currently few and far between in the global mining space.

For this reason, he says Deswik will target small operational improvement studies and the implementation of mine planning processes and systems as its primary workload until there is a commodity price upswing.

He notes that, to cut costs, mining companies are attempting to improve their planning efficiency and accuracy, while simplifying their mining processes to gain the most from their operations; this will ultimately lead to a mine being able to do more work using fewer engineers.

In streamlining operations, mine managers and information technology managers are demanding consolidated and integrated systems to replace the prior assortment of multivendor products in the mine planning software space, says Buffington.

He maintains that, in the current mining climate, mines need improved plans to assist in driving accountability and compliance by providing the required data to make informed operational decisions and reconciliation.

“An added advantage is that there will be less confusion between planning time horizons, such as long-term project planning and operational planning.”

Buffington says the company currently enables mines and exploration projects to make design changes and update their schedules immediately to effectively deal with operational challenges.

He says Deswik’s integration of design and scheduling tools consistently get the desired results, quicker. The company uses its mine planning system and process implementations to help mining operations derive maximum value from projects.

“Our consultants are undertaking several projects in [multiple]commodities using a variety of mining methods to analyse and compare potential improvement opportunities, including increased production, improved haulage networks, reduction in truck numbers, improved development and stoping design and sequences, improved final landform design and selective waste placement.”

Deswik also targets various mining sectors, including opencut coal operations, underground coal mines as well as openpit metals and underground metals operations.

The company’s mining engineers and software developers work in more than 50 countries, providing value-driven solutions for clients through customised software, consulting and training.

In addition to its nine offices worldwide, the company has established a network of partners to provide local technical support.