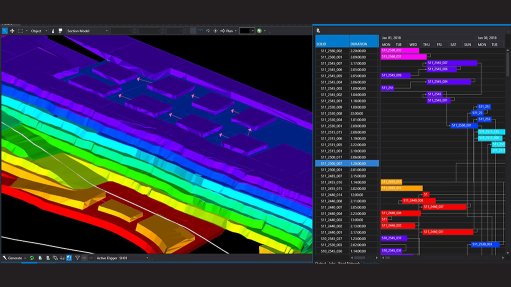

SCHEDULING SOLUTION Maptek’s Evolution 5 delivers an updated interface for scheduling with attributed solids

Software, hardware and services provider Maptek continues to stamp its ownership on the global mine scheduling market through an intelligent optimisation approach, with the company’s latest milestone, Evolution 5, announced last month.

Generating an optimised mine schedule with practical production plans is a unique combination that provides mining companies strategic control, according to the company, which notes that Evolution produces medium-, long-term and strategic life-of-mine schedules which reduce operating costs.

The Evolution 5 is a scheduling solution that delivers an updated interface for scheduling with attributed solids. This upgrade enables short- or medium-term scheduling with block models or solids, and seamless handling of stratigraphic reserves. Further, it represents a more intuitive way to see the source information for scheduling.

Maptek Evolution product manager and mine planning business manager Eduardo Coloma explains that a three-month beta testing program had been incredibly valuable for identifying improvements before the release.

“Customer feedback provides an understanding of what the industry wants to see next, helping us prioritise ideas for our scheduling roadmap.”

He adds that the company is “relentless” in its drive to put smart functionality on the desktop for customers to intuitively apply their scheduling and site knowledge.

Enhanced road network tools save time setting up schedules, leaving engineers more time for analysis.

With Evolution 5, users can now assign dependencies to solids and employ their preferred approach to better control schedules. They also gain more control over processes and the accumulation of parcels. Meanwhile, improved validation of user data before submitting a scheduling job saves time later in the process and improves confidence.

With the Evolution Strategy element, users can define residual capital categories that would apply towards the end of mine life when stockpiles are being depleted, allowing for dynamic adjustment of fixed administration costs.

Reporting and graphing of any data related to the schedule makes comparison easier, allowing engineers “to more quickly and confidently decide on the preferred plan to adopt”.

A new Aggregation module can also be purchased in conjunction with Evolution 5. Targeting stratigraphic deposits, the new module allows for operations, for example, to calculate coal and waste quantities and qualities as they change at each stage of the mining process.

“A flexible, yet automated, step-based workflow allows for users to define parameters, and automatic calculations remove the need for complex scripting. At the same time, transparency is maintained regarding how models were created and what inputs were used,” comments Coloma.

While Maptek always uses leading computational methods, the unique differentiator in the scheduling arena is close collaboration with mining experts to exploit their experience to provide targeted applications.

“No-one has been collaborating as long as Maptek on multi-object optimisation to deliver practical yet value-adding schedules,” says Coloma. “Who else can optimise multiple objectives, millions of blocks, multiple models and multiple processing options simultaneously using a population of initial schedules?”

He adds that, when targeting multiple objectives, Evolution does not return a single schedule, but rather, a set of optimised trade-off schedules. He highlights a study in South America, which proved a significant reduction in preparation and running time.

“We know this technique can provide solutions to probems that are not even thought of yet. The future for Maptek scheduling customers is looking very bright indeed,” Coloma says.

Founded almost 40 years ago to service the mining industry, Maptek offers a unique combination of domain knowledge, technical expertise and engineering resources. The company incorporates automated workflows and optimised algorithms to collect, analyse and circulate critical information within the operational cycle, closing the loop between planning, production and results. Maptek develops solutions that allow for customers to improve safety, productivity and profitability.