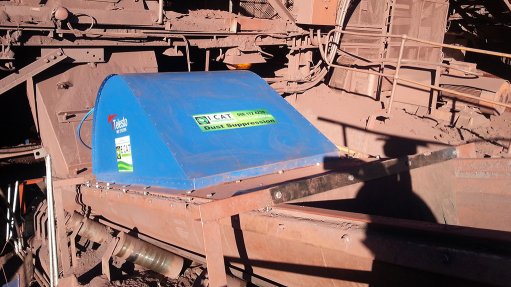

TELESTO DRY MIST The Telesto Dry Mist system is ideal for ore handling, crushing and transfer-point applications

South African ferrochrome producer Assmang’s Beeshoek iron-ore mine ordered two additional Dry Mist dust suppression water mist systems – manufactured by mist technology provider Telesto Mist Systems – from environmental management company I-Cat in September, following I-Cat’s successful design, build and commissioning of the first system at the Northern Cape-based mine in the first quarter of 2014.

I-Cat director Lourens Jansen van Rensburg tells Mining Weekly that the first phase of the project was completed in October and that the second phase will be completed later this month.

He explains that the Telesto Dry Mist system is ideal for ore handling, crushing and transfer-point applications.

“The system enables users to comply with stringent occupational health and ambient air-quality regulations, as it successfully suppresses airborne PM10 dust particles, which refers to coarse dust particle diameters of between 2.5 µm and 10 µm. “The system also uses very little water, compared with similar systems, and no additives are needed to successfully capture and suppress dust,” Jansen van Rensburg states.

Telesto Dry Mist systems remove microscopic airborne dust particles from work environments to improve conditions for staff and machinery, while significantly decreasing the possibility of workplace dust explosions.

The systems generate trillions of 5-µm- to 15-µm-sized particles from a single litre of water. Owing to the size, droplets are electrostatically attracted to dust particles, causing agglomerations to form, which subsequently causes the agglomerated material to fall to the ground.

Supply Contracts

I-Cat supplies its dust suppression solutions to several iron-ore mines in South Africa and Australia, including mining major Kumba Iron Ore's Sishen mine, in the Northern Cape.

The company supplies the Sishen mine with the RDC 20 road-dust- control solution, which is used for dust suppression on the mine’s secondary roads. “We have 17 personnel deployed at the mine who deliver dust suppression services and management, including an environmental officer who monitors and reports on water use and ambient air quality,” explains Jansen van Rensburg, adding that I-Cat supplies five water trucks, including the drivers, as part of its services to Sishen.

The company, through its Northern Cape affiliate, E-Cat Environmental Consulting & Trading, also supplies Assmang’s Khumani mine, which is about 65 km north of Beeshoek, with road-dust-control products, including RDC 20 and GreenBit. The solutions are applied to the mine’s primary and secondary roads.

GreenBit is a bitumen-based product, which can primarily be used on main haulage roads to prevent them from being washed away by rain and to suppress the dust generated by haulage trucks.

Meanwhile, I-Cat Australia supplies RDC 20 for dust control on the secondary haulage roads at ASX-listed iron-ore miner Fortescue Metals Group’s Christmas Creek mine, in Western Australia.