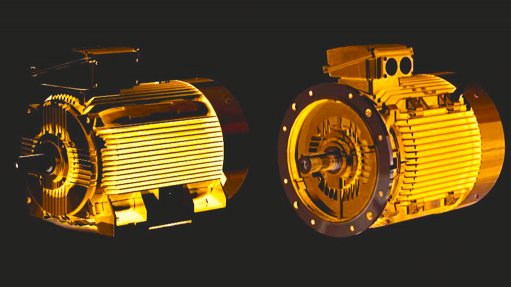

REGAL MARATHON TERRAMAX MOTORS The motors ensure improved efficiency and lower operating costs on rotating equipment such as machinery, pumps, fans, blowers, mixers and compressors

Electrical and mechanical motion-control and power-generation products manufacturer Regal Beloit South Africa will introduce a range of new products to the local market, including the high-efficiency IE2 and premium efficiency IE3 Regal Marathon TerraMAX range of electric motors, in July 2015.

Regal Beloit sales and marketing director Hilton Fortmann tells Mining Weekly that the motors are suitable for the mining, engineering and general industrial sectors, as well as for original-equipment manufacturers and end-users. Through their efficient use of electricity, the motors ensure improved efficiency and low operating costs on: rotating equipment, including machinery, pumps, fans and blowers; heating, ventilation and air conditioning; and mixers and compressors.

“The Regal Marathon TerraMAX electric motors comply with IEC 60034-30 standards. They are equipped with vacuum pressure impregnation (VPI) windings and regreasable bearings from frame 160 sizes and larger – suitable for variable-voltage variable-frequency drives. The motors also function with reduced noise levels,” he points out.

Fortmann is upbeat about the product’s prospects in the local market, owing to companies’ understanding the principle that, with increasing utility power costs, the additional capital outlay for premium efficiency products is “inconsequential to the long-term savings of electrical costs”.

“The more industry accepts premium efficient products and increases the stockholding of the required products . . . the more cost effective the product will be in the long term,” he highlights.

Fortmann further notes that the company will launch the Regal Marathon improved-efficiency scraper-winch motor range next month, which will be used to reclaim and process minerals in heavy mining applications.

“The winch motors range complies with IEC 600034 standards. They are built using high-quality silicon lamination steel and are VPI and variable-speed drive-compatible. They are supplied with high-quality SKF, FAG or NSK bearings and a fully wedged stator,” he says.

Fortmann highlights that the Regal Marathon TerraMAX electric motor range was engineered and designed in the US, with input and technical requirements from all 18 global Regal offices.

“Regal wanted to offer one range of electric motors that would not only meet and exceed all the operating requirements of the global authorities but also offer high efficiencies and reduced carbon emissions,” he explains.

Durability

Fortmann points out that the scraper-winch motors operate in harsh environments, as the motor is exposed to high temperatures, continuous starting and stopping, a high current injection into the windings and frequent repairs. All these aspects were considered when designing the Marathon scraper-winch motors, he highlights.

Therefore, Fortmann says the motor offers class H installation standard, while maintaining a class B temperature-raise standard, as the motor is made of heavy-duty fabricated high-quality silicon lamination steel, which can withstand a controlled “burning out” temperature of 400 ºC.

“Regal also offers introductory and advanced electric-motor maintenance and installation training at all five of the local Regal offices nationally. “On-site training can be arranged locally as well as throughout Africa,” he adds.

Industry Insight

Fortmann says the local industrial motors industry has been exposed to several challenges since 2008, including currency fluctuations and demand decline.

“South Africa has also been exposed to the worst of the global recession over the past 18 months, which has been compounded by the recent strikes in the mining and metals industries.”

He explains that the industrial motors sector has changed over the past five to six years, as end-users are implementing cost-saving initiatives, such as total supply contracts, while also looking for reliable high-quality products.

“At Regal, we provide solutions by offering high-quality, efficient products at competitive rates, and add value to the total cost of ownership. “We take ownership of repairs, condition monitoring and product training all under one roof to maintain the integrity of the product, reduce downtime and significantly reduce costs for end-users,” Fortmann concludes.