As the size of South African coal deposits shrink and operations expect shorter mine lives, miners look to reduce capital expenditure on infrastructure. B&E International’s build-own-operate-transfer (BOOT) plants offer the solution.

“Our expertise and equipment in crushing and screening takes the capex pressure off the customer and relieves them of considerable production risk,” says Ken Basson, director plant and engineering at B&E International. “We can even assume other responsibilities in the value chain, from drilling and blasting to coal conveying and processing.”

This allows the business to flexibly fit in to customers’ value chains, maximising production performance and machine uptime while taking on the risk of meeting the agreed output targets. With research and development as a key driver, new technologies are continuously in the pipeline to meet the changing needs of the industry.

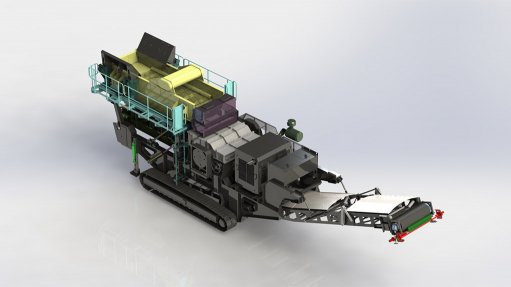

“Our R&D focus has allowed us to develop our own primary coal crushing plant; a high capacity, track mounted unit that is currently under construction and will soon be launched,” says Basson. “The design is aimed at further reducing unit costs that we can achieve when conducting a contract for a customer. Its high volume capacity means better efficiencies while being able to serve multiple small deposits on the same mine site.”

Water conservation in the coal beneficiation process is another element of the company’s R&D. It is exploring practical options for ‘dry separation’ technology for coal plants, in collaboration with a local university. Traditional water-based coal washing technology is a major consumer of water in mine plants.

Process optimisation is also a service that B&E International provides for customers, based on its years of experience in designing, constructing and operating plants, he says.

“Whether a project is greenfield or brownfield, we can assist in providing solutions and addressing challenges,” he says. “For existing plants, our engineering team can identify and address constraints in the process – whether the equipment is ours or a competitor’s. We conduct detailed studies on how customers can remove bottle-necks from their plants.”

Equipment is designed, built and maintained by B&E International’s experts at their well-equipped facilities in Kempton Park, Gauteng. As a member of JSE-listed Raubex Group, B&E International is B-BBEE-compliant and works closely with mines, project houses and contractors.