END TO CORROSION The polyurethane compound used in Schurco Slurry's wet end pumps and components decreases the degree of corrosion found in the highly corrosive copper processing process

Heavy-duty centrifugal slurry pump manufacturer Schurco Slurry has successfully supplied 20 new pumps to a copper mine, in the Northern Cape, and has received an order for spares – valued at over R600 000 – from a copper company in Zambia.

The products supplied will be used across the two clients’ operations, including in copper processing and tailings facilities management.

“We have seen a favourable increase in demand in Zambia, which has led to our Zambian supplier maintaining a reasonable amount of stock for a variety of our components,” says Schurco Slurry Pump applications and projects manager Marc Young.

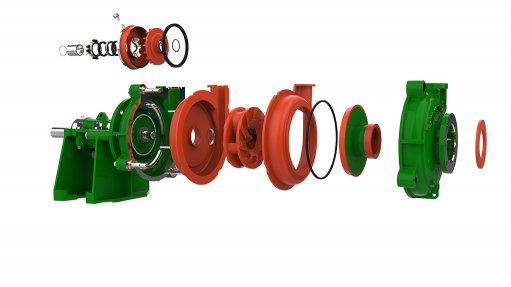

Schurco Slurry manufactures high quality heavy duty horizontal and vertical slurry pumps, replacement pump parts, and provides pump services to a wide array of markets globally.Supply to the Northern Cape and Zambia includes mainly its pumps, liners, impellers and other spares, all of which are suited to the corrosive environments found in copper processing.

“We offer wet-end spares manufactured from our specially formulated polyurethane compound, which forms part of our own proprietary mix and is developed with the assistance of the base-compound suppliers,” he adds.

Polyurethane is a proven corrosion- and abrasion-resistant material, owing to its unusually high tear and chemical-resistance properties, which has led to an increased wear life that is about 66% longer than that of other linings in the market.

The research on, and development and manufacturing of these pumps and spares takes place at Schurco Slurry’s manufacturing facilities, in the US and South Africa.

“Schurco Slurry has highly trained and skilled engineering and process staff who have a combined experience of over 150 years,” says Schurco Slurry president and owner Nicholas Schur.

The company’s research helps to mitigate the challenges that arise because of variable minerals processing, which, in turn, is the result of a high degree of changes in the orebody.

“Consequently, our slurry pumps do not have a standard calculated formulation and vary from mine to mine and application to application,” states Young.

Further, the South African branch holds extensive stock at its head office, in Johannesburg, while Schurco Slurry’s holding company, in the US, also holds extensive stock for global markets.

Schur says the company also supplies to copper mines in the Democratic Republic of Congo, South America and Eastern Europe directly and through third parties.

“Plans are under way to expand into African territory, and Schurco has established an office in Dubai to service the Middle East and surrounding territories,” Young concludes.