Photo by: Bloomberg

JOHANNESBURG (miningweekly.com) – Baobab Resources continues to advance a definitive feasibility study at its pig-iron and ferrovanadium project, in Mozambique’s Tete province, with pilot-scale smelting trials currently under way to investigate the behaviour of vanadium during smelting and subsequent oxidation treatment.

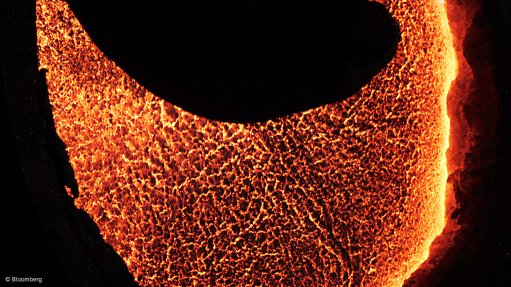

Using a tilting furnace, 45 kg of pig-iron product had successfully been produced, which Baobab believed was further evidence of the project’s potential.

Initial results indicated a recovery of in excess of 75% vanadium to the hot metal, which was in accordance with earlier bench-scale testwork.

“It is important to note the low level of copper and also to mention that the levels of sulphur, phosphorous, titanium and other deleterious elements will further reduce with the removal of vanadium,” the company said in a market update on Thursday.

Between four and six 200 g samples of pig-iron would then be subjected to vanadium recovery testwork using various additives and levels of oxygenation to determine optimised conditions for two larger tests to produce a sufficient amount of vanadium-rich slag for subsequent characterisation.

Both pig-iron and slag samples would be used for marketing purposes.

Meanwhile, pilot-scale direct reduction trials, using bulk samples of Tenge oxide iron-ore, Massamba carbonate and local thermal coal product, were ongoing at test facilities in the US.

A first round of kiln trials was now complete, while a second round was scheduled to start in the coming weeks to confirm the rotary kiln route as a suitable technology with an accompanied process guarantee.

Moreover, marketing studies covering the merchant pig-iron market, vanadium market, as well as the supply and demand dynamics of steel production in the Middle East, had been completed.

“The combination of low-cost high-quality Tete pig-iron and competitive ocean freight to the Middle East indicates a production cost advantage over Middle Eastern-produced direct-reduced iron, placing Tete pig-iron as an ideal raw material source for an increasing focus on rebar manufacturing capacity in this region,” noted Baobab.

The company, meanwhile, continued discussions with potential strategic partners in northern Asia and the Middle East.

Progress was also being made in terms of securing access to port, rail and power, with negotiations with both public and private sector entities at an advanced stage. Discussions concerning coal offtake agreements were also under way.

In addition, technical logistics studies were well under way to ensure economically feasible methods to evacuate the pig-iron product from the project site through either the ports of Beira or Nacala.

Geotechnical and hydrogeological drilling were complete and would be incorporated into the pit optimisation, mine scheduling and reserves classification studies that were currently under way.

The mining title application was ready for submission and work had started on the drafting of the mining contract, while the environment-, safety- and health-impact study, resettlement action plan and social development plan were all making progress and were largely on schedule.

Commenting on the project’s progress, MD Ben James said results, to date, were in line with expectations and continued to derisk the asset.

“We are also running a continuous process of reviewing and revising our process flow sheets and capital and operating expenditure models to further optimise the fundamentals of this already very competitive project,” he said.

The International Finance Corporation holds a 15% participatory interest in the Tete project.