Minister launches long-term acid mine water solution

Acid mine drainage project manager Craig Hasenjager tells Mining Weekly Online's Martin Creamer that gypsum can be recovered in new long term government plans. Video and editing: Darlene Creamer.

TCTA project manager Craig Hasenjager

Photo by Duane Daws

GERMISTON (miningweekly.com) – Water Minister Nomvula Mokonyane on Wednesday launched a long-term project to turn acid mine drainage (AMD) into safe water for commercial use as either industrial or potable water.

The Minister chose the old south-west vertical shaft area of the dormant East Rand Proprietary Mines (ERPM) to launch the long-term solution to remove the sulphates.

She spoke amid elaborate infrastructure already built under the auspices of the State-owned Trans Caledon Tunnel Authority (TCTA), which has been mandated by an inter-Ministerial committee on AMD to tackle the challenge mines have left in Gauteng, the province of gold.

Made up of the Ministers of Water, Mineral Resources, Finance, Science and National Planning, the inter-Ministerial committee had given the green light to implement the short-term action plan in the Western, Central and Eastern basins of the Witwatersrand goldfields.

This plan was to prevent an outpouring in the Western basin and breaching of the environmental critical level in the Central and Eastern basins at a combined cost of R2.3-billion.

The next big step will involve R10-billion more to introduce a long-term solution with the help of either reverse osmosis or desalination technology, to remove salts the short-term solution leaves in the water.

Recovery of saleable gypsum in the long-term solution along with the two-thirds collaboration of the mining sector will help to soften the cost blow once the long-term solution is implemented, which will also create a revenue stream from the sale of the cleaned-up water.

TCTA project manager AMD Craig Hasenjager explained to Creamer Media’s Mining Weekly Online that government action was triggered in 2002 after uncontrolled decant of acidic metal-laden water flowed into the Tweeloopies river in the Western basin of the Witwatersrand goldfields.

“It had a pH of three-and-a-half and all the metals and salts in it,” he recalled. (Also watch attached Creamer Media video).

That sparked realisation that the Central and Eastern basins of the Witwatersrand were also filling up and also threatening to decant.

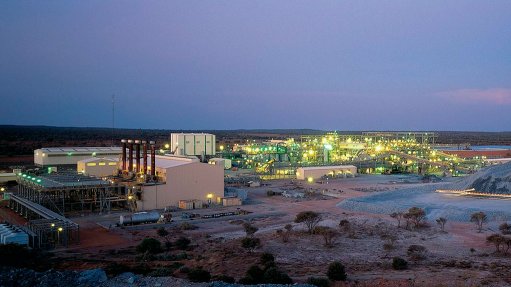

The new water treating infrastructure shown to dignitaries and the media at the old south-west vertical shaft area of the mined-out ERPM has been replicated in the Eastern basin.

The Central basin plant visited is able to treat 82 megalitres a day and the soon-to-be-commissioned Eastern basin will be able to treat 110 megalitres a day.

In the Western basin, the Rand Uranium plant has been upgraded and TCTA is allocating water to would-be technology providers in a bid to find lower-cost solutions.

Meanwhile, two submersible pumps draw the acidic mine water from ERPM’s now-capped old south-west vertical shaft and transfer it into a splitter box, where limestone is added to lift the pH to 5.8, ahead of its piping to a reactor.

In the reactor, mine tailings sludge, returned from the thickener, is mixed with the AMD water and more lime is added to lift the pH to 9, in order to remove the metals.

In this short-term phase, water is cleaned, with gypsum crystallisation reducing the salts but not removing them, which is why the long-term solution is required, to clean the water for safe commercial use as either industrial or potable water.

While in the short-term phase the pH is corrected and the metals removed, the water remains too high in salts for use.

The long-term solution will actually take out those salts, opening the way for safe use of the water.

Implementation of the long-term solution has to be preceded by a full environmental-impact assessment, which will take from 12 months to 18 months to complete.

Another two to three years will then be required to build the long-term plant itself.

Price-wise, the plan is for the water recovered in the long-term project to eventually come into line with the going potable water tariff, which it well exceeds currently. (Also watch attached Creamer Media video).

BENEFITS OF INTERVENTION

Had government not intervened, the flow of AMD into the larger environment, including the natural river system, could have caused widespread environmental risk through the release of various hazardous metals.

Through the pumping and treating of the acidic mine water, invaluable groundwater resources have been shielded from toxic contamination.

The interventions have also brought about important gains in the socio-economic development of near-basin communities, where small enterprise development has resulted, along with preferential procurement and skills development for historically disadvantaged South Africans.

Job creation reached the 1 000 mark at the peak of the construction of the treatment plants.

CONVERGENCE TO LONG-TERM SOLUTION

The decision to move to a long-term, permanent solution, has the potential to increase the water supply to Gauteng, South Africa’s economic hub.

The aim is to increase water supply to the Vaal River system, a key driver of continued socio-economic development, defer for 30 years the need to go beyond Phase 2 of the Lesotho Highlands Water Project and provide an opportunity for water allocation reform.

The environmental impact assessment is scheduled for completion by June 2017 so that construction of the long-term project can begin in January 2018, reach commissioning in November 2019 and start operating in February 2020.

PROJECT FUNDING

The combined R12-billion capital cost outlook for short-term and long-term solution is based on a funding model that the Minister explained involves equitable allocation "to us as government, to the mining sector and to water users”.

As the contributor to AMD, the mining industry should carry some share in the costs, but in a manner that did not "unnecessarily overburden the sector and threaten jobs”, the Minister said,adding that water use charges would not place water users in “a worse-off financial position than they would be if nothing had been done”.

WESTERN BASIN IN KRUGERSDORP

The treatment capacity of the upgraded Rand Uranium treatment plant in the Western basin was increased to a point at which the uncontrolled decant was stopped and the water quality of the Tweelopies river improved.

Further upgrading is being implemented to lift the treatment capacity to 50 megalitres a day.

Already completed is the construction of a new pump station to increase the pumping capacity to the environmental critical level (ECL). These works are being executed in partnership with Sibanye Gold, which owns Rand Uranium.

CENTRAL BASIN IN GERMISTON

This new high-density sludge water treatment plant, in operation since December 2014, ensures that the water level is kept at the ECL.

Gold mining company Central Rand Gold, which requires a consistent underground water level, donated R30-million worth of pumps to this project, where the TCTA also enlisted the help of gold-mining company DRDGold to co-dispose the AMD sludge on their tailings dam and to occupy the mine's property free of charge.

TCTA is in the process of appointing an operator on a short-term contract to undertake the operation and maintenance of the Eastern basin plant, with half of the works earmarked for black-owned companies as part of the aim to create broad-based empowerment capacity within the sector.

EASTERN BASIN IN SPRINGS

The soon-to-be-commissioned high density sludge plant in the Eastern basin is the largest of the three plants and one of the largest of its kind in the world. This operation will also dovetail with mining’s broad-based empowerment aspirations.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation