Vitaglass - ‘reinforcing’ the trend toward maintenance-free, glass fibre reinforced gratings

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

For nearly 80 years, Vital Engineering has been providing clients across various industry sectors – from food and beverage, marine exploration, minerals sands processing, architectural, construction, petrochemical, mining, and power generation – with a range of products.

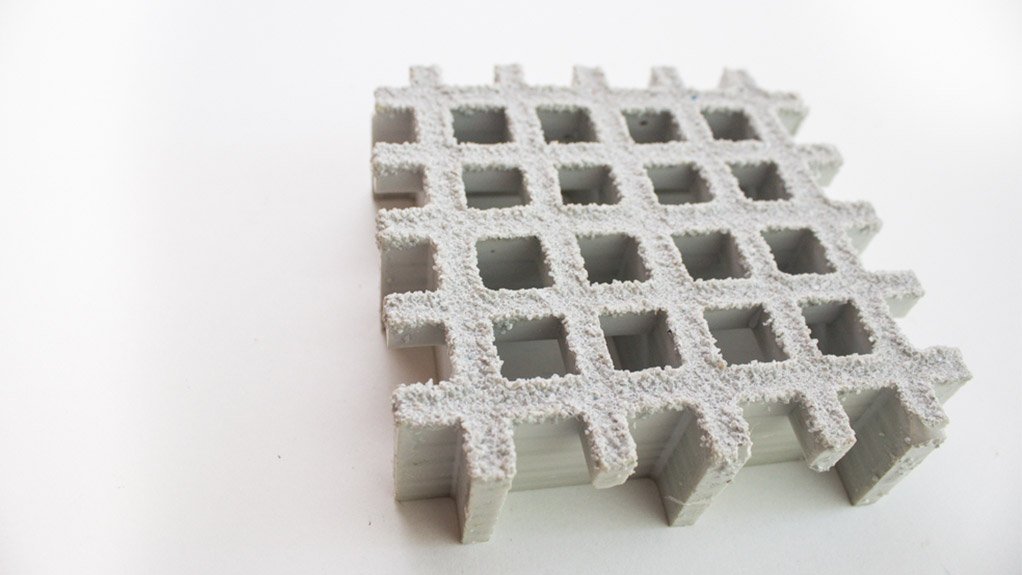

This comprises non-slip floor gratings, walkways, stair treads, safety handrails, pressed floors and treads, in a variety of materials including austenitic ferritic fibreglass and special finish coatings.

Over the past few years the company has seen a significant growth in demand for their Vitaglass range of glass fibre reinforced products. This can be attributed to a growing preference for maintenance-free construction materials; which can be observed in mining, industrial and construction projects in Africa, and South Africa.

According to Glen Pringle, Technical Director at Vital Engineering, the Vitaglass range fits extremely well into their product portfolio. Depending on the consulting engineer’s specifications there is usually a requirement for this type of product; which is very adequately filled by glass fibre reinforced grating hand railings and solid flooring.

“The material offers clear advantages in terms of price, weight and zero maintenance requirements - without compromising on design or safety specifications,” Pringle points out.

He explains: ‘The inherent advantages of glass fibre reinforced products are plentiful. It possesses good load-bearing strength at approximately half the weight; and furthermore, its corrosion-resistant and fire-retardant properties make this product particularly suitable in harsh, or highly corrosive conditions; or in situations where potential sparking or fire could be a risk (such as in underground mining or at sea on an oil rig).”

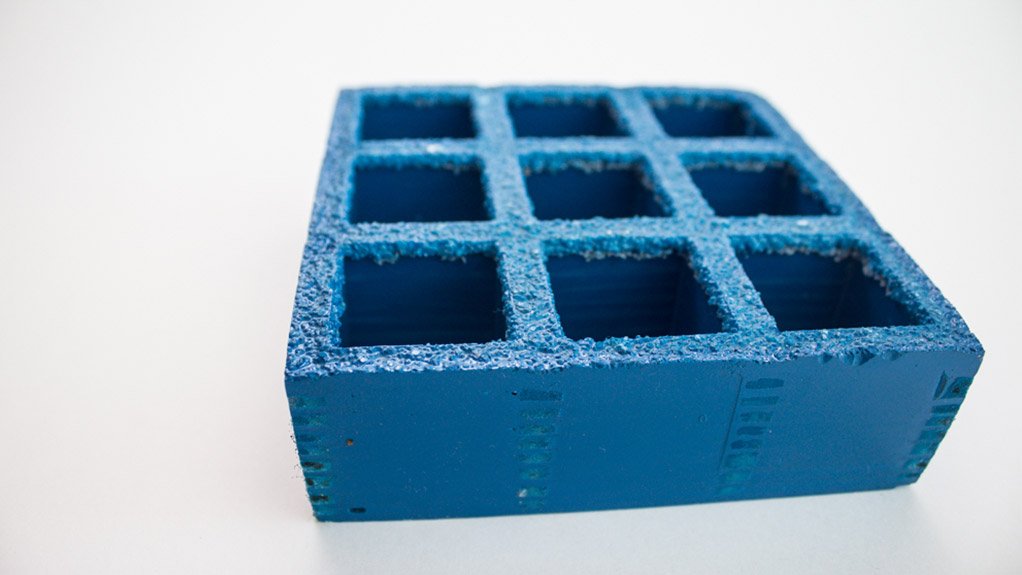

Another significant advantage is that component theft for the purpose of reselling (such as with copper) is eliminated in many instances. Vitaglass products can also be produced in a wide variety of colours, which can be applied for safety purposes like colour-coded emergency walkways; but also for architectural, and aesthetic considerations. An example of the latter is the property development sector, where sun diffusers and burglar bars can be specified by the architects concerned, and produced in colours which complement the building design.

Pringle emphasises that fibre reinforced products (gratings, hand railings, sections) are not a form of plastic and should not be perceived as such – it is a saturated glass fibre reinforced resin product. Although fibreglass is not recyclable, the production process is relatively clean and it is viewed as an environmentally-friendly product; which is suited for applications in so-called ‘green’ buildings, where a reduced carbon footprint is the objective.

“Glass fibre reinforced products have been widely adopted in first world countries like America, Canada, Australia and across Europe. Although South Africa is still behind on this trend, we are definitely catching up,” he says.

“Vitaglass is a very dynamic product, with new applications emerging continually. Because of the versatility of the material, the applications are endless and are only limited by the imagination of the manufacturer and the client. New applications for Vitaglass are found almost every day,” he remarks.

From a manufacturing perspective, glass fibre reinforced gratings can be either moulded or pultruded – a continuous process of manufacture featuring constant cross-sectioning of the material - pultruding resulting in a stronger material. Structural strength can also be improved by a ‘ribbed’ design for greater load-bearing properties at a lighter weight. The material properties can further be adjusted by additives resulting in fire retardant, UV resistant, and differing composite characteristics.

“Of course there are some applications where mild steel and stainless steel cannot be replaced, and for that reason, Vital will continue to supply our product portfolio in the full range of materials,” he comments.

The company however cautions clients against making ill-advised choices of materials which could solely be based on price considerations; and which may be of inferior quality, thereby compromising structural strength and ultimately, human safety.

Vital Engineering is able to provide their clients with bespoke products, tailor-made to fit projects and product specifications. With this in mind, Pringle highlights the importance of engaging Vital during the early stages of the project, so that sufficient time is allowed to develop custom-made products if required, by understanding the client’s requirements.

To date, Vital’s glass fibre reinforced gratings have been used in a wide variety of projects and sectors, including mining (including mineral sands processing plants as well as underground and above-ground walkways, conveyer belts and more), petrochemical and power generation, to the food and beverage (breweries and wineries), architectural, aquaculture, maritime and offshore oil and gas sectors, to name but a few.

Some other different and interesting projects where the Vitaglass range has been deployed include at a pan-African university, 4 x 4 vehicle accessories, and lockers for fire departments where the grid structure allows for transparent and well-ventilated storage. The range has also been used in electrical substations, where the inherent non-conducting properties of the fibreglass are especially valuable.

“The local and pan-African mining sector poses challenging and diverse product requirements. Mining majors from all over the world design and operate mines on this continent; which results in a wide range of design styles, specifications and international standards. Vital’s Vitagrid, Vitaglass Vitex and Maclock ranges are all extremely well suited to these requirements, due to their versatility and varying properties,” he explains.

“Given the evolving product lines and the clear advantages offered by the Vitaglass range, there will always be a market for this product, and a new application waiting to be discovered,” concludes Pringle.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation