Science council heavily involved in mining research and development

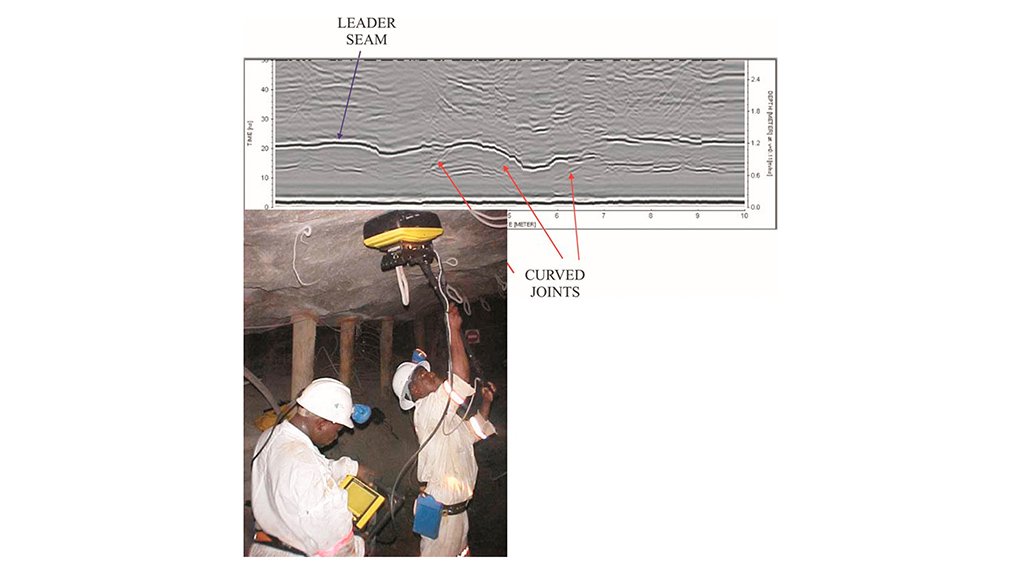

SEEING THROUGH ROCK: A team (left) uses ground-penetrating radar on the roof of a mining excavation with (above) the resulting image

Photo by CSIR

NAVIN SINGH We need to develop our own solutions for our own problems

Photo by Duane Daws

AWARENESS An underground gas explosion is recreated at the CSIR’s Kloppersbos testing facility, north of Pretoria

Photo by CSIR

Although the new Mining Precinct (or Mining Hub) initiative has rightly attracted a lot of interest, the mining and minerals research and development (R&D) activities of the Council for Scientific and Industrial Research (CSIR) – a key participant in the Mining Precinct – are not confined to that initiative.

“Across the CSIR, we actually have four units – [major divisions] – that are directly involved in mining R&D,” points out CSIR Natural Resources and the Environment Unit mining and mineral resources competence area manager Navin Singh.

The four units concerned are Natural Resources and the Environment, Materials Science and Manufacturing, the Implementation Unit, and the Meraka Institute. “These are the main business units involved in mining research, but any and all other competence areas across the CSIR can and do provide support, when necessary,” he points out.

The CSIR, on its website, provides the background against which its mining R&D activities take place: “South Africa is home to a majority of the sought-after minerals commodities in the world. The industry faces significant challenges, such as ageing mines, increasing depths of mining operations, low grades, narrow tabular ore deposits, and highly complex geotechnical environments, as well as high labour-intensive dependence. These challenges expose mineworkers and communities living close to mining areas to various hazards and their related risks.”

The CSIR’s mining and minerals R&D does not only involve four business units, but is also distributed geographically, involving the CSIR campuses in Pretoria and Johannesburg, as well as safety-critical testing facilities associated with mining at sites north of Pretoria and in Johannesburg. Coordination is thus required. The CSIR has frameworks to provide such coordination. They are called Research Impact Areas (RIAs). These RIAs are firmly aligned to key national priorities. “RIAs allow organisationwide research programmes to address strategic stakeholder needs through access across a wide portfolio management,” states Singh. “Furthermore, the RIAs allow for the clear articulation of the CSIR identity, and development and communication of CSIR capabilities.”

“Mining has been identified as an RIA,” he explains. “This allows us to create collaborative solutions by drawing on the strengths of all competences across the CSIR. We believe this is the way to go forward. The mining activities of the CSIR are firmly aligned with the Samerdi (South African Mining, Extraction, Research, Development and Innovation) strategy. This served as an input document into the Mining Phakisa (see Mining Weekly August 13, 2015).” The aims are to create a competitive and safe mining industry and to re-establish the country’s mining R&D capabilities (this latter aspect is covered by the Mining Precinct).

CSIR research activities cover the whole mining value chain. “Holistically, the CSIR is ideally positioned in that it has a variety of skill sets it can bring to bear on problems in mining,” he highlights. “Whether we’re talking about extraction, development of beneficiation of postprocessed materials, optimisation of energy usage or land rehabilitation after mining stops, we can assist, without overlapping the roles of the Council for Geoscience (exploration) or Mintek (minerals processing).”

Government, through the Department of Science and Technology, has identified the CSIR as a key driver in the re-establishment of the country’s mining R&D capabilities, which have been degraded and fragmented over a number of years as a result of the fall in resources prices, which led the country’s public and private sectors to both cut their expenditures in mining R&D.

The CSIR’s core focus in mining is on extraction – but “extraction” conceived in broad terms, including science, information, health and safety and improved management. This is why four units are involved in its mining R&D activities. Health and safety is a particular focus, with the CSIR fully committed to assisting in the achievement of the mining sector’s Zero Harm initiative, launched jointly by business, labour and government in 2003. The CSIR works closely with the Mine Health and Safety Council.

The Mining and Mineral Resources competence area of the CSIR Natural Resources and the Environment engages in research into mine seismology, mine geophysics (delineating of geological structures in the rock mass), mining engineering and coal processing. (The other competence areas of CSIR Natural Resources and the Environment are Ecosystems, Environmental Solutions for a Green Economy, Global Change and Water Resources.)

The CSIR Implementation Unit hosts health and safety-critical testing facilities, as well as doing research into respirable dust (specifically focused on minimising the impact of silica dust in the mine atmosphere underground, because of the danger of silicosis). Another area of focus is the human factors in the workplace, such as fatigue management and ergonomics. Safety- critical testing facilities for mining have three main elements, namely self-contained self-rescuers (compact breathing apparatuses for individual miners to use in emergencies), hoist rope testing (checking the load-bearing capability of mine hoist ropes, which is done at a specialised CSIR test facility at its Johannesburg campus) and mechanical testing.

“The other safety area in which we operate is methane and coal dust explosions,” adds Singh. “We have the Kloppersbos testing facility, north of Pretoria, which is also used as a training facility. We did a lot of R&D into coal dust and methane explosions there, but now it’s used mainly for awareness training.”

The CSIR Meraka Institute is focused on R&D regarding information and communications technology (ICT) platforms. Within the Institute, there is a dedicated group working on ICT platforms for mining operations, with the “communications” aspect being especially important. “They are also looking at the creation of a ‘smart mine’ to better understand data, to convert that data into information, that information into knowledge and that knowledge into wisdom.”

The involvement of CSIR Materials Science and Manufacturing is mainly concerned with the development of robots and sensors that could be used in mining to facilitate the development of automation and mechanisation in the local industry.

“These are the main units of the CSIR involved in mining,” he notes. “But, to reiterate, any and all other CSIR business units can and do provide support to mining programmes and projects, where necessary.”

The CSIR is undertaking a number of R&D programmes and projects to benefit mining. These are grouped into three main themes – to optimise and increase the efficiency of current mining practices; to develop next-generation mining practices; and to develop nonexplosive rock breaking methods.

“Within these three areas, there is a strong focus on mine geophysics to delineate the [gold or platinum] reef and so determine where mining should take place. The idea is to ‘see’ ahead of the rock face,” he explains. “To this end, we are strengthening sensor development and underground communications capability to allow for real-time information management. The third element is the development of platforms that will ultimately lead to automated and mechanised mining. All these three aspects are closely interlinked: when you can determine what is ahead of you, good communications and real-time information will allow you to instruct your automated machinery and/or robots what to do next.”

To these ends, CSIR researchers are working on a number of technology projects. One of these is aimed at improving ground-penetrating radar and bore-hole radar and also improving how they are used. Other geophysical techniques are also being improved and developed.

The organisation has already developed a geotechnical sensor for use in coal mines, called ‘Goafwarn’. This can measure rock mass deformations, which involve micro- seismic fractures, to give early warning of rock failures. Goafwarn sensors are installed in the roof of mine excavations. These sensors are already in use in coal mines, but now the CSIR is working on a hard-rock counterpart, which is called ‘Rock Pulse’. This is now being developed in conjunction with a local platinum mine and will also be tested in the much-deeper gold mines in due course.

Further, the research agency is involved in the development of a device that will be able to determine if a rock, in the roof of an excavation, is loose. Such loose rocks can pose a threat to the safety of the miners working in the area. This detector will employ both acoustic and thermal sensors and is being developed in cooperation with other South African research institutions.

The CSIR is also considering mounting sensors on robotic platforms. In addition, it is working on autonomous vehicles which could be used underground. This research involves developing suitable propulsion systems and achieving the required manoeuvrability, given the safety requirements and limited spaces such platforms would face.

“CSIR Natural Resources and the Environment has another group that looks at what is called ‘postmining landscapes’. The aim is to explore the use of land once mining is completed. The first step is the restoration of the mine site to a condition as close as possible to that of its premining state,” he reports. “This includes research into minimising the environmental impact of current operating mines. The ultimate aim is to make sure that the environmental impact from mining is as small as possible.

“South Africa needs its own mining R&D capability,” concludes Singh. “The country has a unique mining environment with deep, hard rock mines. We need to develop our own solutions for our own problems, with the caveat that the technologies developed here can be applied elsewhere. Most importantly, these technologies need to be developed cooperatively and collaboratively to ensure we get the best solutions.”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation