Solutions provider helping Zambia tackle mining challenges

LONG-TERM SUSTAINABILITY To ensure the long-term sustainability of a mine, it is essential to always keep operating costs down

The mining and minerals processing sectors present some of the most challenging production environments, as the large-scale operations are often located in harsh, remote areas, explains technical solutions provider BMG.

As a way of mitigating some of these operating challenges, BMG Zambia country manager Ian Smith explains that BMG assists mines – in Zambia and globally – with product selection to fulfil mining and processing equipment application requirements, by providing solutions that significantly reduce their initial project expenses and limit ongoing capital costs.

“BMG’s integrated engineering solutions service offered to the Zambian mining sector encompasses a complete electromechanical capability, which includes customised plant design, product selection, installation, commissioning and support service.”

BMG supplies several mining companies and operations in Zambia, including First Quantum Minerals (FQM) and FQM’s mining and operations; Kansanshi Mining, Konkola Copper Mines, Lumwana Mining Company’s Barrick Gold operations, Kalumbila Minerals, Mopani Copper Mines, China Nonferrous Metal Mining-controlled Luanshya Copper Mine, NFC Africa Mining, Chambishi Metals, Chibuluma Mines, Chambishi Copper Smelter, Kagem Mining, and Gemcanton Investments Holdings as well as Lubambe Copper Mine.

He further explains to Mining Weekly that BMG’s energy efficient drive solutions are designed to meet the exact needs of the mining and minerals processing sectors, while simultaneously ensuring improved asset availability and the lowest cost of ownership.

“These robust drive systems can withstand heavy loading and operation in extreme conditions and are able to control equipment installed at great distances.”

By optimising alternating current (ac) drive applications for every plant design, Smith explains that BMG provides “dependable” solutions that improve productivity, save energy costs, reduce maintenance requirements and extend the service life of equipment.

“To ensure the long-term sustainability of a mine, it is essential to always keep operating costs down, from the time the initial capital investment is made to when operational- and maintenance-related expenditure is required,” he explains.

Smith further notes that costs can be limited by correct product selection, which helps extend the service life of equipment and its components, improves the efficiency of processes, reduces maintenance requirements and saves energy costs.

The correct product selection, he explains, plays a “vital part in the ongoing pursuit of enhancing productivity at a micro and macro level”.

It is this ongoing pursuit, he notes, which led to BMG offering “premium” drives through the Danfoss brand, which incorporates the high power VLT drive and the Vacon range.

“BMG is now able to deliver low-voltage drive solutions up to 5 MW in several customisable configurations, such as options pertaining to serial communication, output filters, mains power supply, ingress protection, input and output, and safety.”

Danfoss drives are designed to operate in harsh, dusty environments and in high ambient temperature conditions, without derating, and can also be installed in environments containing relatively high levels of contaminants.

Standard VLT and Vacon drives, Smith adds, have lengthy motor cables for mines with a large-scale layout.

“They are fully compatible with all ac motors and integrate seamlessly into programmable logic controller fieldbus networks. These drives have built-in request for information (RFI) filters, which ensure reliable operation of all other electrical equipment on the same installation,” he explains, noting that no additional RFI filters are required on the input of the drive, which saves space and installation time and costs, compared with conventional ac drive solutions.

Danfoss drives, he further enthuses, have a compact design and an intelligent heat management system for reduced project and operating costs. The back-channel cooling concept for VLT high-power drives reduces contamination of the drive’s electronics, resulting in the increased life span of the unit.

This cooling concept is also an effective solution for reducing heat dissipation within the drives installation area. By removing the drives’ dissipated heat directly, mines are able to reduce cooling system requirements, thereby saving on capital and long-term energy costs.

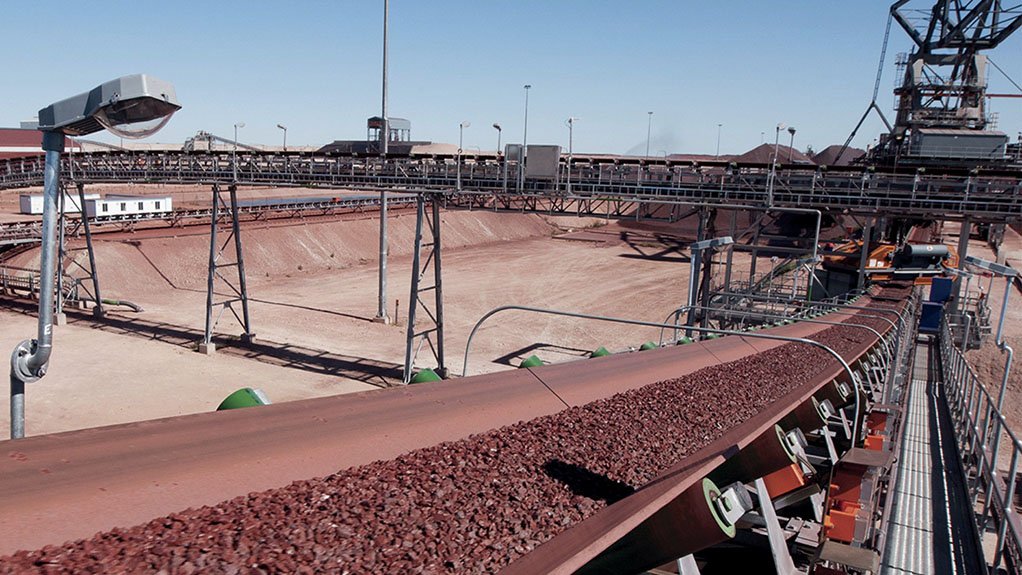

VLT and Vacon drives are used for many applications in mining, including the control of mine ventilation fans, for smooth acceleration and deceleration of long conveyors, for electric-driven dewatering pump skids and for the reliable operation of slurry pumps.

These drives are also used for all mining and minerals processing equipment applications and bulk materials handling facilities.

“Danfoss variable-speed drives are fully compatible with BMG’s high-power motors, which are available in an IP66-compliant version and in different power or frame size combinations. Motor life span is improved by winding all motors with Class H insulation and a Class B temperature rise,” he avers.

Installation and changing out of the BMG high-power motor range is made easy, owing to the oversized terminal box and removable gland plate. These motors, which are tested in accordance with the stringent standards of the South African Bureau of Standards, as well as international standards, are shock pulse monitoring ready to facilitate vibration monitoring and testing.

BMG’s high-power gearbox range incorporates the Sumitomo product range, such as the Paramax and Hansen, Nord and Zollern brands, which offer optimised gear tooth profiles to reduce wear and noise levels. This also extends the service life of BMG’s gearboxes, which the company is able to customise for specialised applications.

BMG has two branches in Zambia, in Lusaka and on the Copperbelt in Kitwe, which offer a 24/7 support service for its full product range through technically competent workshops and field service teams.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation