‘Simple build, unique design’ set Hydra-Cell pumps apart

Hydra-Cell P200 replaced tradional metering pumps spraying abrasive latex solution on coal.

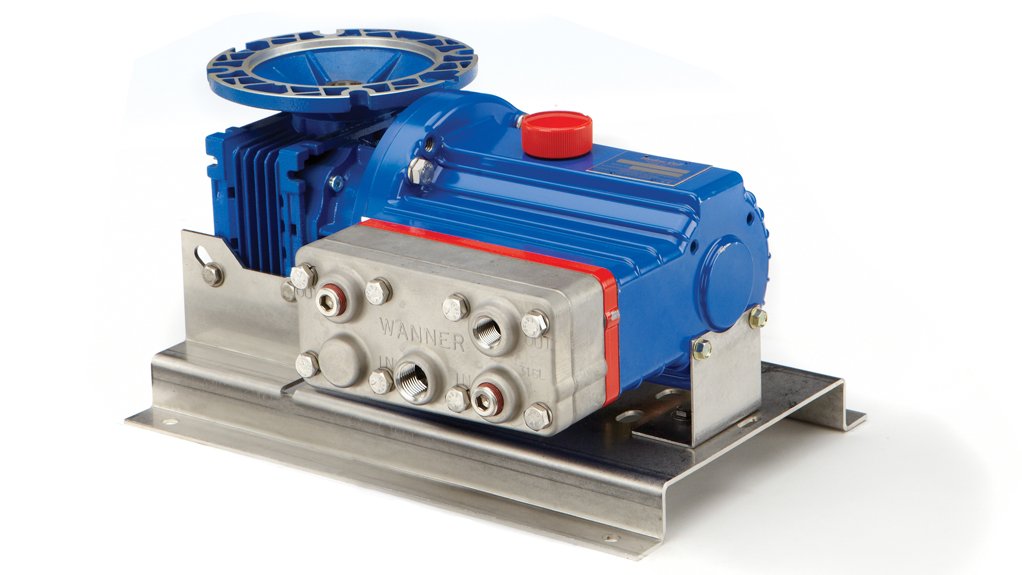

Hydra-Cell pumps manufactured in the US by Wanner Engineering have solved problems for industrial pump users worldwide. A simple build and a unique design with no dynamic seals offer significant advantages in many mining and quarrying applications. Visitors to Electra Mining Africa may well find an unexpected answer to their own pumping issues at the stand of Johannesburg-based Monitor Pumps & Systems – a long-established Hydra-Cell distributor in South Africa.

Specifying pumps for operations in mining, quarrying and tunnelling is not always straightforward. Many applications can be exacting, not only in performance levels, but also in terms of the liquids handled and the working environment.

Despite the variety of designs, brands and capacities on offer, pump selectors often face a combination of requirements that together seem difficult to reconcile.

Pumps of Type A may easily meet flow specifications, but struggle to maintain adequate pressure. Those of Type B satisfy both, but are vulnerable to rapid wear when handling harsh liquids or abrasive solids. A pump of Type C can cope with all these problems but cannot deliver the required smooth flow without heavy reliance on pulsation dampeners.

In trying to ensure against the consequences of a wrong decision, the pump buyer may be inclined to overspecify. The fact is that choosing any unsatisfactory option is at best a compromise and one that over the life of the pump could prove very expensive. The cost is typically seen in high maintenance expenses, excessive downtime and early replacement because of pump failure.

It is now more than ten years since one of South Africa’s leading mining companies broke out of a similar situation when it ran a 12-month trial of an exceptionally versatile pump (a Hydra-Cell model) on a seal-flushing application on a system that transfers abrasive phosphate slurry to a slimes dam.

Gland seals in the main transfer pumps had to be kept at 50 kPa above main pump pressure to maintain a water seal and prevent slurry from pushing through behind the impellor – resulting in abnormal wear with consequential downtime, maintenance and call-out costs. However, the conventional seal-flush pumps were themselves failing. They could deliver water at pressure, but the grey water in use was ‘recovered’ and the flush-pumps could not handle the abrasive particles carried in it.

Following a successful trial, the mining company was sufficiently confident to install a further 18 Hydra-Cell pumps, replacing the original seal-flush pumps on this application.

The section engineer at the mine had looked for a solution that would save on maintenance costs, which ran into millions of rands each year. Five months after the new pumps were installed, Monitor’s liaison engineer was able to report that the mine had not experienced a single system failure or needed to call out a technician in connection with seal-flushing, validating the R1-million investment in new pumps, baseplates and motors.

The Hydra-Cell design concept was developed in the 1970s by William F Wanner, cofounder of the pumps manufacturer.

The pumps have no packing or dynamic seals and are leak-free. A virtually pulse-free pumping action is achieved hydraulically by the sequential flexing of multiple diaphragms manifolded in a single head. The diaphragms isolate oil in the pump’s hydraulic end from all wetted parts. The two liquids are not in contact, so many different liquids – hot or cold, thin and nonlubricating or viscous, acidic or caustic – can be safely handled.

The pump also allows for pumping of abrasive solids in suspension without fine filtration.

The Hydra-Cell is a positive displacement pump, with flow unaffected by system pressure. The flow rate is simply controlled electronically by varying motor speed.

All these features are combined with pressure capability up to 100 bar or, in most models, higher.

Applied to the mining industry, among others, this is a strong combination. Pumps used for drill head cooling and for dust suppression duties above or below ground are themselves likely to be operating in difficult, dusty conditions. Feedwater can often contain particles that will damage pumps with dynamic seals, and quickly block fine filters.

Physically compact and energy efficient, using relatively small motors, most Hydra-Cell pumps fit readily into mobile mining or quarrying machinery.

The original Hydra-Cell pump, working at pressures up to 70 bar and flows up to 30 ℓ/min, was the first in a model range that has continually expanded, while also evolving technically.

Five years ago, Wanner launched the first of its T Series models: pumps of substantially higher horsepower and performance. More developments have followed, with the range of 16 basic models currently in service covering flows from 0.0045 ℓ/min up to 595 ℓ/min and pressures up to 345 bar. Further models are in the testing stage.

These investments have made Hydra-Cell technology available in new marketplaces, with many applications already known, but previously beyond effective reach, adds Wanner.

Hall M3 Stand 11

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation