Screens Excite Sa Iron Ore Giant

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

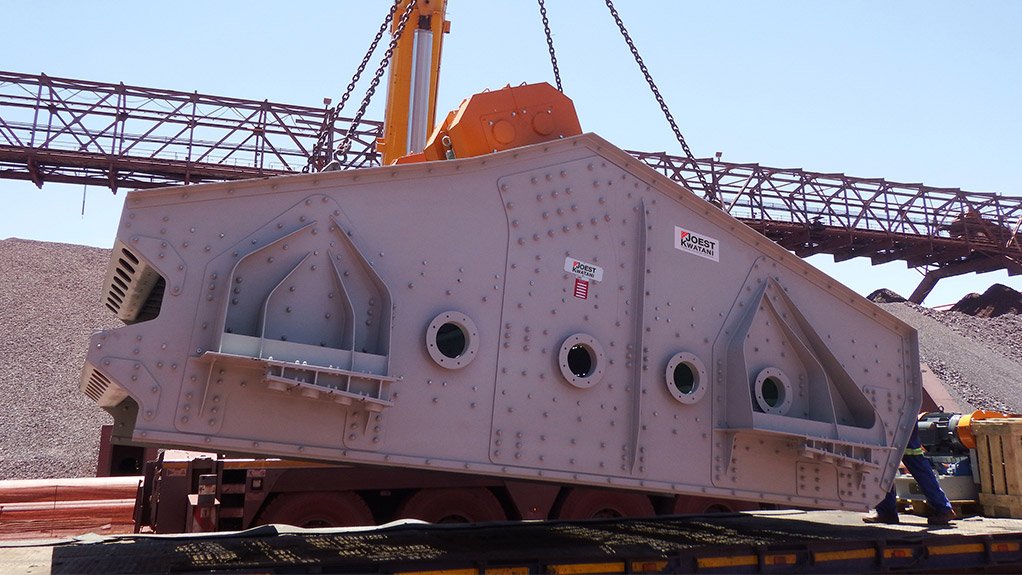

Joest Kwatani recently successfully completed another large screen equipment project for one of the largest iron ore operations in Kathu, Northern Cape, South Africa. Joest Kwatani has enjoyed a 25 year relationship with this mine, considering the performance of its robust screens in these very arduous working environments.

Kim Schoepflin, managing director of Joest Kwatani, says this was the largest retrofit undertaken at the mine in such a short period, and that the project was completed within budget and well before the contractual completion date. “We have always enjoyed fast track projects; we find that they are always extremely efficient and, more importantly, accurate,” she says.

Joest Kwatani undertook the project over two phases, which involved designing, manufacturing, installing and commissioning 57 screens in just over a year. Schoepflin says the second phase was the largest of the two involving the installation of 22 screens in the mine’s cyclone plant and 15 in its washing and screening facility.

In the washing and screening plant, seven were primary double deck and eight secondary double deck screening machines. These size iron ore material which is fed to the cyclone plant, where the balance of Joest Kwatani’s screens are single deck vibrating units used to separate course and medium size material.

Schoepflin says that one of the biggest challenges was working in an existing plant structure and screening machine footprint while ensuring the productivity at the mine was uninterrupted. Significant design challenges had to be overcome so that the existing plant could accommodate the new screens. This included designing screens with low side plates and developing a fit-for-purpose spreader beam to lift and place the units above one another in order to place them into their position in the washing and screening plant.

In order to keep the programme on track, the company gradually phased itself into the second stage of the works, and then followed a detailed project plan over the entire contractual period. However, Schoepflin notes that flexibility is key to working successfully on mining projects. “Although our plan was aligned to the mine’s production programme, we have always had the ability to adjust and think on our feet to accommodate the operation’s strict production requirements,” she says.

All the screens feature Joest Kwatani’s exciter gearboxes that increase G-forces and therefore improve the mine’s recovery of ferro-silicon material and screening efficiency, while reducing total cost of ownership. “Our screens have been known for being workhorses since their inception, and will place the operation in a very good position for the future,” she says. ,The screens were manufactured at the company’s premises in Kempton Park, Gauteng. Depending on the installation schedule at the mine four to eight units were transported to the mine site every month, after undergoing stringent testing at the company’s in-house test facilities.

The screens were received by Joest Kwatani’s 15 dedicated personnel stationed at the site who oversaw the installation and commissioning of the screens. The contract also includes a one year maintenance agreement which will be honoured by the company’s dedicated office in Kathu.

This is just one of many examples of Joest Kwatani’s ability to deliver a robust bespoke solution to the mining industry. And, it is no surprise that it continues to dominate the screening market in the iron ore rich Northern Cape.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation