Production at Sasol’s Shondoni mine set to start next month

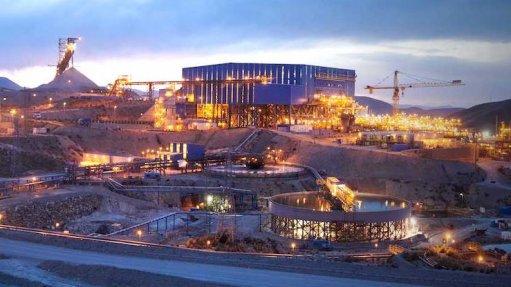

SHONDONI MINE Sasol’s new Shondoni Mine is expected to produce its first coal this month

The construction of energy and chemicals group Sasol’s Secunda-based Shondoni mine is nearing completion, with first coal production expected this month.

The first key milestone – the handover of surface infrastructure and licensing of the winder and shaft complex – was achieved in February.

Sasol awarded engineering company WorleyParsons South Africa (SA) the engineering, procurement and construction management contract in January 2012 for the new Shondoni mine, which will replace the ageing Middelbult mine and protect the baseline feedstock for the coal-to-liquids (CTL) operations within Sasol Synfuels.

The mine is expected to produce 9.2-million tons of coal a year using a conveyor system that will transport the coal by means of a 21 km conveyor belt to Sasol Coal Supply (SCS). The single-belt, curved overland conveyor is one of the longest conveyor belts in the industry and one of the last key elements that needs to become operational before underground coal can be fed into the system.

Since February, the surface infrastructure at the mine has been completed to facilitate its full operational status. Occupation by production personnel began in April and will ramp up to a total of 1 190 site-based mining employees, working in three eight-hour shifts. Two office blocks include 156 offices, covering an area of 4 950 m2.

The complete building footprint is 24500 m2 and includes operational change houses, a sewage treatment plant with capacity to process 200 000 ℓ of effluent daily, 460 covered parking bays, roads, access control, paving and power. This complements the fully operational shaft system that incorporates personnel, ventilation, decline and materials shafts with fully licensed winders. Secondary systems such as fire suppression infrastructure, service water reticulation, security fencing, lighting, walkways and electrical reticulation are also all in place.

WorleyParsons SA Shondoni project lead civil engineer Frikkie Naudé says the construction of the surface infrastructure included moving 1.092-million cubic metres of earthworks, the use of 39 500 m3 of concrete and the supply and erection of 9 300 t of structural steel. Further, 36.5 km of road was constructed, 37 200 m2 of concrete and block paving laid, and power generation equipment with a capacity of 21.5 MW installed.

WorleyParsons head of department and project engineering manager Gary Bullen says the company has a good relationship with Sasol and, as a team under the guidance of Sasol, with the assistance of all its service providers, the company performed well and reached its objectives within the adjusted time constraints.

The team is now tasked with ensuring that the second key milestone is achieved, whereby the mine is set to produce its first coal through the underground conveyor system and then transport the coal by means of the conveyor belt to SCS, for use in the production of synthetic fuels.

The unique overland conveyor belt represents one of the longest of its kind in the mining industry and will provide Sasol Mining with a cost-effective and efficient means of transporting its own coal to Secunda. Coal is delivered from the Shondoni mine decline shaft to a 15000-t-capacity surface bunker for temporary storage before being transferred using the conveyor to the SCS site. A 4 000-t-capacity surface bunker was also constructed for temporary storage at SCS.

“The surface structure is accessible to the client and the winder and shaft complex has been licensed by the inspectorate and is now fully operational, with all the infrastructure support in place,” concludes Bullen.

The Shondoni mining project is part of a R15.3-billion project undertaken by Sasol Mining to replace three of its ageing coal mines in the Secunda area. On completion of the project, the three mines will contribute to the supply of 42-million tons of coal a year to Sasol Synfuels. The Secunda area remains one of the largest underground coal complexes in the world.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation