Sands retreatment plant to begin production next month

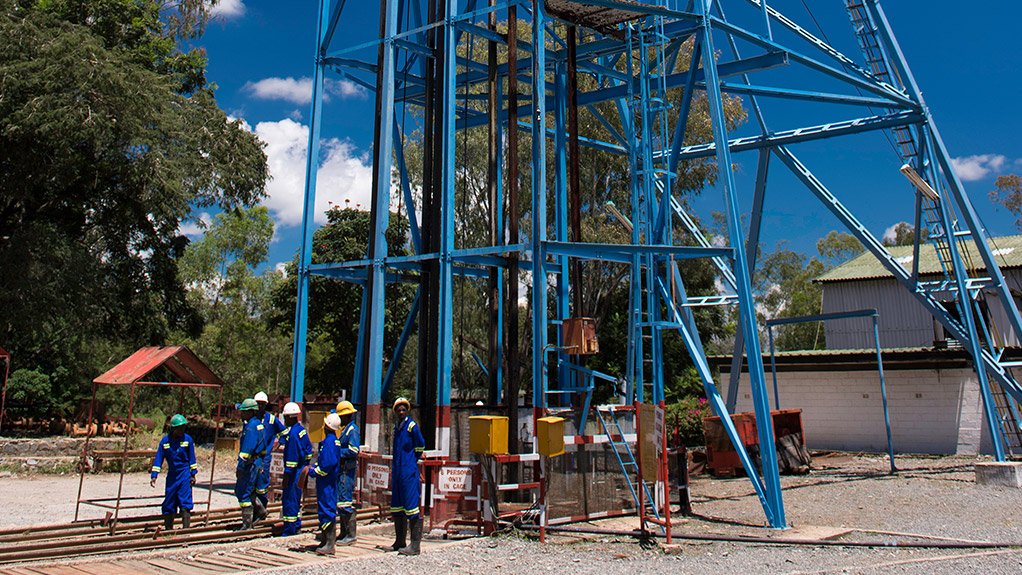

MAZOWE MINE The shaft currently reaches a depth of about 800 m, but Metallon is considering expanding laterally on strike

RICH HISTORY Mazowe has been operating since 1963 and has historically been known for achieving high grades of up to 35 g/t

Plant commissioning and production at Zimbabwe gold producer Metallon’s Mazowe mine’s sand retreatment plant are expected to start next month, company CEO Kenneth Mekani tells Mining Weekly.

Once completed, the plant will mill 60 000 t/m, overtaking Metallon’s 35 000 t/m Shamva mine as the company’s second-highest gold producer.

At the time of going to print, groundworks construction was nearing completion and site erection of the sand retreatment plant, which is being manufactured in Benoni, South Africa, by heavy engineering machine shop Baldmin Engineering, was expected to have started by the end of August.

Mekani says Baldmin Engineering has manu- factured about 70% of the equipment required for the plant.

He notes that, subsequent to the site erection having been completed, the plant will undergo wet commissioning, which involves water being pumped through the plant to ensure that all equipment is working according to design and that there are no leaks in the system.

Mekani explains that the sand retreatment plant will employ a combination of flotation and cyanidation, allowing for an 83% recovery of the gold in the mine’s sand dump, which has an average grade of 1.3 g/t.

Metallon has also contracted South African wastewater solutions provider Fraser Alexander to build a new tailings dam facility at Mazowe, the construction of which, Mekani hopes, will also start next month.

He notes that the plant upgrades also necessitated that the mine improve its power capacity, resulting in a power line already being rerouted and a new substation that is currently being constructed.

The mine’s power capacity will increase from about 6 MW to 8 MW once the substation has been completed.

Mekani notes that Mazowe has been operating since 1963 and has historically been known for achieving high grades of up to 35 g/t.

“However, the recovery systems at the mine were not very efficient and a significant amount of gold was lost to the dumps.”

He adds that these losses were estimated to be as high as 4 g/t, prompting the company to develop a retreatment strategy.

“We cannot continue to rely on the grades at the mine and we now need to look at improving the volumes,” Mekani states, adding that, once the sand retreatment and tailings dam facility have been commissioned, the company will shift its focus to underground expansion at Mazowe, which currently has a Joint Ore Reserves Committee-compliant resource of 1.9-million ounces.

The shaft currently reaches a depth of about 800 m, but Mekani says Metallon will consider expansion of the mine’s underground network laterally on strike before deepening the shaft, owing to the promising exploration work conducted by the company’s geological team.

He tells Mining Weekly that a successful underground expansion programme at Mazowe, which he hopes will start early next year, will increase the mine’s gold production from about 27 000 oz/y in 2015 to over 50 000 oz/y by the end of 2016.

“Our geologists are working hard to realise our dream of making the Mazowe mine the largest gold producer under Metallon. Based on the data that we have received, this is not only a dream but also something that we can realise,” he asserts.

Meanwhile, the company’s Redwing mine, also in Zimbabwe, is expected to resume production by the end of this month, Mekani says.

The mine was closed in 2008 during Zimbabwe’s hyperinflation crisis in favour of the company’s other operations. It was subsequently flooded, owing to the shaft being located beneath the Mutare river.

The company is dewatering the shaft using pumps; however, Mekani notes that financial constraints and the prioritisation of other projects have led to the company only partially dewatering the shaft, as it was found the mine could still produce without completely dewatering the shaft.

He adds that Redwing will start production at 15 000 t/m when operations are resumed, following a refurbishment project that is currently 70% complete. It will then ramp up to 22 000 t/m in 2016, which is the current plant capacity.

Mekani points out that, once Redwing reaches full production capacity, more than 700 jobs will be created, with mostly locals being employed from the surrounding area.

“These are exciting times for us as a mining company and Zimbabwe’s largest gold producer.”

He notes that Metallon has always strategically placed itself as a low- cost producer and, despite the current depressed gold price, the company is well positioned for the future.

“Metallon has proved that it can operate and deliver in Zimbabwe during a time when several companies are pulling out of the country or shutting down operations. We are demonstrating that we can make money in Zimbabwe and we are reinvesting that money in the country.”

He highlights Metallon’s investments in Zimbabwe: the company is operating four mines, developing the Redwing mine and exploring the possibility of developing other mining operations in the country.

“We hope to continue playing our role as a Zimbabwe gold producer and contributing to the economy and social upliftment of the country’s people,” Mekani concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation