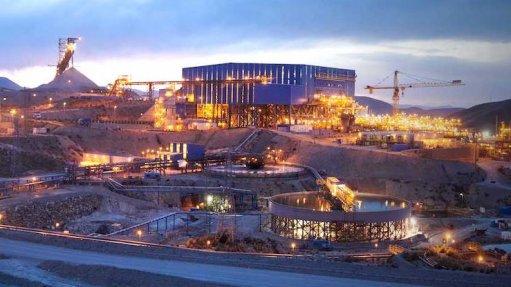

Mining veteran calls for ‘zero deaths’ target as his own operation notches up 5 589 fatality-free shifts

SHIVA URANIUM MINE Every employee has a responsibility to not only care for their own safety but also that of their colleagues

Photo by Oakbay Resources

KOOS JACOBS Despite having recorded 5 589 fatality-free shifts as chief safety officer at Shiva Uranium, Jacobs is of the opinion that there is nothing to celebrate

Photo by Oakbay Resources

It is incumbent on all stakeholders to prevent deaths in South Africa’s mines, says uranium and gold miner Shiva Uranium safety manager Koos Jacobs.

In May 1995, Jacobs was the chief safety officer when a massive tragedy occurred at Shaft No 2 at the Vaal Reefs gold mine, in the North West. A locomotive fell down the main vertical shaft onto the personnel cage, killing 104 of his colleagues in what remains South Africa’s worst mining disaster since democracy.

Five years before that, in 1990, he was also present when an explosion occurred in the same mining district. The incident at Shaft No 9 of Vaal Reefs killed 22 miners underground.

“Despite the passage of time, the memories linger. In fact, over the past 47 years, I have been involved in many mines, 33 of them in the safety and health department. I have lost many a colleague and friend as a result of accidents. Each one was a great loss, whether I knew them personally or not,” Jacobs laments.

He says that this is why, despite having recorded 5 589 fatality-free shifts as chief safety officer at Shiva Uranium, he is of the opinion that there is “nothing to celebrate”.

“Each year, miners are killed in accidents that can be prevented and it is therefore my personal responsibility to ensure the safety of Shiva’s about 770 employees,” Jacobs states.

He adds that mining fatalities remain a major challenge in South Africa, despite the numbers having decreased “markedly” since the mid-1990s, with 84 having been reported in 2014, compared with

270 in 2003, the same year government embarked on a legislative and regulatory drive to ensure safer conditions.

“But our target should actually be zero and this is achievable,” Jacobs asserts.

He points out that, in 2015, labour unrest, retrenchments, a drop in global demand in the commodities market and other economic issues dominated the headlines in mining, while deaths of miners continued to be a statistic.

“In South Africa, we have our own unique issues when it comes to mining safety. It is a fact that we have the deepest mines in the world, which are going ever deeper.

“Geological conditions, the heat, provision of breathable air and vertical transport of people also present increasing challenges,” Jacobs adds.

Additionally, he points out that the cost of ore mined per ton has escalated significantly in recent years, which has resulted in companies finding it increasingly difficult to find adequate funding to plough back into high-quality training to equip miners with the requisite skills.

Further, Jacobs notes that there are three kinds of incidents that have the most potential for harm, namely shaft incidents – even though they have a low occurrence rate – falls of ground and seismic events, which occur regularly, and transport- and machinery-related incidents.

There are also other types of potential incidents that receive high levels of preventive attention. These involve electricity, the use of explosives or chemicals, slipping and falling into excavations, toxic gas and the inundation of mud or water.

Additionally, Jacobs says health and hygiene matters also receive a high degree of preventive attention.

Safety Tips

He explains that, as a safety officer, the most common concerns experienced on a daily basis include noncompliance with prescribed personal protective equipment standards by employees, poor housekeeping, and lack of communication and transfer of information between supervisors and subordinates, as well as noncompliance by employees with procedures and standards prescribed by management.

Jacobs stresses that every employee has a responsibility to not only care for their own safety but also that of their colleagues.

“They should not do anything, or fail to do anything, that may jeopardise them or their colleagues. This can be achieved through continued improvements in training on safer work procedures, task observations, continuous communication and the application of a zero-tolerance policy on any noncompliance to standards, procedures or specifications.”

He says, on the side of management, they must stop planning for incidents, like setting injury targets, and instead target zero injuries and fatalities and believe this is possible and achievable.

Jacobs states that companies must also develop their own safety systems that should be audited by external, independent entities to measure compliance.

He adds that legislation will always be necessary in a major industry such as mining and must continuously be reviewed and updated as the need arises. “Self-regulation is also crucial.”

Jacobs explains that government can then prescribe certain standards, which can be included in an overall safety system for regular auditing. He says the State can also call for regular reporting by companies, as well as compliance measurements.

“This is akin to applying the principle of not doing what you expect but what you inspect,” he says.

However, Jacobs notes that, if government is to legislate companies’ safety and health activities, it must also ensure it has the necessary manpower and skills to monitor compliance.

He emphasises that this should not result in any animosity between government and employers, but should inculcate a culture of joint responsibility and cooperation.

“This will also compel companies to uncover any potential undesired aspects and find solutions, while also ensuring that regular offenders face the necessary disciplinary action,” Jacobs concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation