Renison tailings retreatment project, Tasmania

Name of the Project

Renison tailings retreatment project (Rentails).

Location

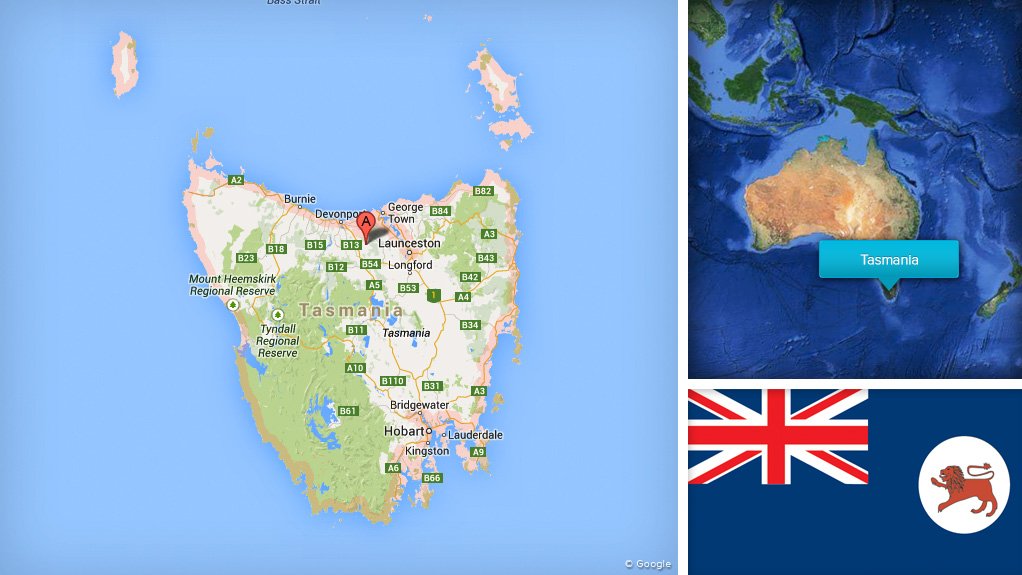

The project will be located about 1.5 km north-west of the existing Renison tin concentrator, in Tasmania, and adjacent to the existing tailings storage facility.

Client

Rentails, in which Metals X owns a 50% share through the Bluestone Mines Tasmania Joint Venture.

Project Description

Renison produces about 7 000 t/y of tin in concentrate.

The project proposes to expand production by about 5 400 t/y of tin and 2 200 t/y of copper through the reprocessing and recovery of tin and copper from the existing historical tailings at Renison. This is based on the retreatment of about 21.6-million tonnes of historical tailings reserves at an average grade of 0.45% tin and 0.23% copper.

The project will have a mine life of about 11 years at a two-million-tonne-a-year treatment rate, with the opportunity to treat additional tailings and intermediate seams. The flow sheet comprises grinding, sulphide flotation, ultrafine gravity separation, tin flotation and tin fuming.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

The project has a pretax net present value, at an 8% discount rate, of A$260-million and an internal rate of return of 37%, with a payback of 3.2 years.

Value

Construction capital costs have been estimated at A$205-million.

Duration

Not stated.

Latest Developments

Rentails is considering financing options with its joint venture partner and determining the timing of long-lead items, final approvals and the capacity of suppliers to service Rentails.

Key Contracts and Suppliers

None stated.

On Budget and on Time?

Not stated.

Contact Details for Project Information

Metals X, tel +61 8 9220 5700, fax +61 8 9220 5757 or email reception@metalsx.com.au.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation