Buffalo Coal in push to slash debt and improve safety and operational efficiency

AVIEMORE ANTHRACITE COLLIERY Buffalo Coal plans to increase its permanent workforce by 120 people by 2020 after the completion of a new Aviemore adit

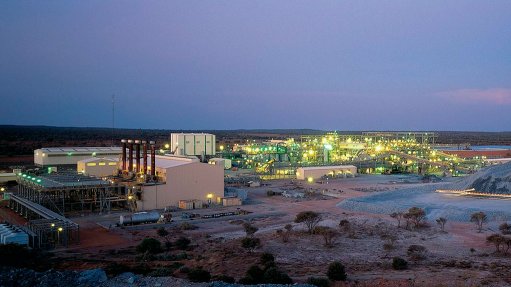

CENTRAL HUB The Coal Fields logistics and processing asset has a 1.5-million-ton-a-year wash plant, a stockpile capacity of 100 000 t and rail loading capacity of 1.4-million tons a year

ROWAN KARSTEL Over the past six years, Buffalo has continued to increase production at its mines through the implementation of mechanisation

South African bituminous and anthracite coal miner Buffalo Coal is determined to repay all its debt and continue to improve safety standards, while improving overall operating capability to ensure its operations become optimally efficient, says interim CEO Rowan Karstel, who was speaking to Mining Weekly during an exclusive tour of the company’s operations in June.

He notes that the company has a R200-million loan with specialist banking and asset management group Investec, which it intends to repay in the coming years. Karstel enthuses that the company made R171.4-million in revenue in the first quarter of this year, compared with R142.5-million during the same period in 2016.

Buffalo also recorded adjusted earnings before interest, taxes, depreciation and amortisation of R5.3-million for the three months to March 31, compared with a R11.2-million loss in the prior comparable period. Therefore, it is “well on its way to achieving this goal”, says Karstel.

He highlights that there has been a significant improvement in Buffalo’s safety statistics since 2016, when it recorded a lost-time injury frequency rate (LTIFR) of 0.97 for every 200-million hours worked. However, as at May 12, the company’s LTIFR was 0.35, as it recorded two lost-time injuries (LTIs) at that time, compared with the ten LTIs recorded during the previous comparable period. The company last recorded a fatality in 2014.

Karstel attributes this safety record to an increased focus on, and the monitoring of, leading indicators, the introduction of visible, felt leadership, starting with the company’s senior executive leaders through to middle management, along with an incident cause analysis investigation method for Level 4 high potential incidents, such as fall-of-person, vehicle collision, fall-of-equipment/material, and fires and explosions, among others.

The TSX- and JSE-listed company produces high-quality thermal and metallurgical coal at its operations near the town of Dundee, in KwaZulu-Natal. The company’s two operating mines are the Magdalena thermal coal mine and the Aviemore anthracite colliery, with a calcine processing plant located nearby, at its Coal Fields site.

In 2010, Forbes & Manhattan Coal acquired the Magdalena and Aviemore mines through the acquisition of Slater Coal, which was subsequently renamed Forbes Coal and then Buffalo Coal Dundee. Between 2013 and 2015, US-based private-equity firm Resource Capital Fund extended a $29-million convertible loan to what is now Buffalo Coal.

On average, Buffalo produces 1.6-million run-of-mine (RoM) tons of coal a year and processes 950 000 t of saleable product, 50% of which is exported, with the balance used locally in the steel, paper and other domestic sectors. The company has no contracts with State-owned power utility Eskom and currently has no plans to supply coal to the utility.

The company employs 1 134 people, including 506 contractors. Karstel says the company plans to increase its permanent workforce by 120 people by 2020, after the completion of a new Aviemore North adit and the introduction of two additional sections.

He comments that, over the past six years, Buffalo has continued to increase production at its mines through the implementation of mechanisation and introducing continuous mining machines to its thermal coal operations. Prior to mechanising its mines in 2011, the company produced an average of 822 000 t/y of coal.

Moreover, Karstel points out that the company’s operations are “strategically located” about 204 km from the Richards Bay Coal Terminal (RBCT), in KwaZulu-Natal. “This is a huge benefit for export purposes, as we are located on the lower end of the Ermelo coal rail network, which is below the Overvaal tunnel bottleneck. Therefore, we are always able to get trains to transport our coal to the RBCT.” He adds that the company, in terms of the Quattro programme, has an allocation of 240 000 t/y.

The Quattro programme facilitates the access of junior black economic-empower- ment coal producers to the coal export market.

Further, Karstel says that all its coal is sold in rand terms through third-party traders, with a large portion of the coal sold by diversified mining and marketing company Glencore channels. He explains that this has been done to derisk Buffalo from railing and port risks, as well as rand:dollar exchange rate volatility.

Magdalena has its own 1.5-million- ton-a-year wash plant and its 950 000 t/y of saleable product is trucked 30 km to the nearby Coal Fields facility, which the company owns and operates. The saleable product is stockpiled and railed from the Coal Fields siding.

Buffalo’s Coal Fields logistics and processing asset has a 1.5-million-ton-a-year wash plant, stockpile capacity of 100 000 t and rail loading capacity of 1.4-million tons a year.

“Coal Fields also comprises a 60 000 t/y calcine processing plant, the company’s main offices, a weighbridge, a clean coal handling system, a loading yard, rail sidings, workshops, shunting locomotives and other general infrastructure,” says Karstel.

The RoM coal from Aviemore is also trucked 14 km to Coal Fields, where it is washed at the anthracite plant and processed for sale. The mine’s thermal coal is washed at Magdalena. The discard material from Aviemore is trucked to Magadalena, where it is stockpiled on the mine’s waste dump.

Magdalena and Aviemore are underground operations that use the bord- and-pillar mining method. The mining contractor at Magdalena is STA Coal Mining Company, while Buffalo undertakes the mining operations at Aviemore.

Magdalena, which is a four-section underground operation, is accessed by an adit through an opencast highwall, which is called the Tembelisha shaft. The colliery operates on a two ten-hour shift basis from Monday to Friday. The colliery has an overland conveyor system that transports RoM coal from the mine to the wash plant.

The mine has a 2 359 ha footprint and hosts 61.6-million mineable tons in situ (MTIS), and has a remaining life span of 15 years. It produces RoM coal with an average calorific value of about 28 MJ/kg, an ash content of about 17%, volatiles of about 20% and a sulphur content of about 1.8. The colliery yields duff, peas and nuts as products.

Karstel states that the company is working towards opening up new ground at Magdalena, called Panel 417. “It consists of four development ends 78 m long and it will open up new production reserves at the mine,” he says, adding that this decline development is progressing well and is on target and within budget and was due for completion by the middle of this month.

He further reveals to Mining Weekly that the company has prospecting rights for property adjacent to Magdalena, which, he says, could potentially add about five years to the mine’s current life span.

Meanwhile, he points out that, at Aviemore, there are also two drill-and- blast mining sections, where scoops are in operation. The company will introduce two new sections at the colliery, which is accessed through a highwall adit, once the new north adit is completed in 2020.

“The Aviemore plant runs at 50% capacity but, with the introduction of the two additional sections, the plant will run at full capacity and will lead to reduced fixed costs,” Karstel comments.

The Aviemore site is 5 544 ha in extent and has 42-million MTIS, with a remaining life span of 15 years. The mine produces RoM coal with an average calorific value of about 28 MJ/kg, an ash content of about 16%, volatiles of about 8% and a sulphur content of about 2.8. It produces duff, peas and nuts.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation