PTM eyes Q4 production start at Waterberg platinum play

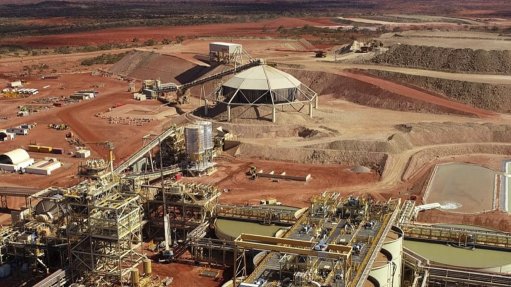

JOHANNESBURG (miningweekly.com) – Platinum explorer Platinum Group Metals (PTM) continues to advance construction at its 82.9%-owned Western Bushveld Joint Venture (WBJV) Project 1 Platinum Mine, or Project 1, in the North West, in accordance with plan and cost budget estimates.

PTM’s focus for this year would remain on the successful start-up of production at Project 1.

Driving this objective, the group outlined that it had expanded key operational leadership roles in recent months, appointing a general mine manager, production manager, equipment specialist, engineering specialist, safety and environment manager and training superintendent.

The development was currently 70% complete and over 7 638 m of access development had been completed at the North mine decline by November 30.

REEF ACCESS

The stockpiling of Merensky reef development material had begun over the quarter ended November 30, with some 106 084 t on surface, while the South boxcut had been completed.

Underground mining during 2014 had advanced the material decline to some 949 m and the conveyor decline to 741 m.

In total, over 2 206 m of access development had been completed at the South Mine.

“Project 1 is planned to be in production in the fourth quarter of the year and, after a planned two-year ramp-up period, steady-state production is scheduled at 275 000 oz of platinum, palladium, rhodium and gold.

“The company’s current cash position is projected to be sufficient to complete the mine build to initial production,” CEO Michael Jones said in a statement.

Meanwhile, the company was planning to release a resource update for its Waterberg JV project in the first quarter of this year.

ADVANCED INFRASTRUCTURE

Reporting on the “major items” completed during the 2014 calendar year, Jones outlined that the company had built the foundations and civil works for the primary mill, while the structural steel for mill and flotation circuits were largely complete.

The mill bearings were in place and the mill itself had been delivered and lifted into position.

Power infrastructure remained on track, with an initial 10 MVA installation complete and an additional 10 MVA service scheduled for completion later this year.

The stands and civil works for the conveyor from the North Mine to the mills had been completed, while the exterior of the North mine change house, which could accommodate 1 200 people, was complete, and the interior currently in progress.

The exterior of the South change house, which would accommodate 500 persons, had also been completed.

Advancing the project’s basic infrastructure, PTM stated that the electrical substation and connections for the North and South mines were in place, as well as water infrastructure for construction and development.

The pollution control dams had been completed, while development along the Merensky reef and first underground raises had started.

“In terms of mining activities, the North mine development [of] five mine blocks is advancing as planned, while construction of the chairlift and conveyor has started.

“Civils and most of the steelwork for the surface ore silo and conveyor transfer points has been completed, while the equipment maintenance shop is now in place,” PTM outlined.

The site’s computer access control system had been installed and was operational, while the security control center and mill control buildings were nearing completion.

The social and labour plan, safety, environment and government reports were filed on time and had received “good feedback”.

PTM incurred a net loss of $5.6-million for the three months ended November 30, driving a loss a share for the period of $0.01.

By the end of the three months, about $343-million of development and construction investment had been completed at Project 1 within a total peak-funding estimate of $502-million.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation