Powering all aspects of the African mining sector

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

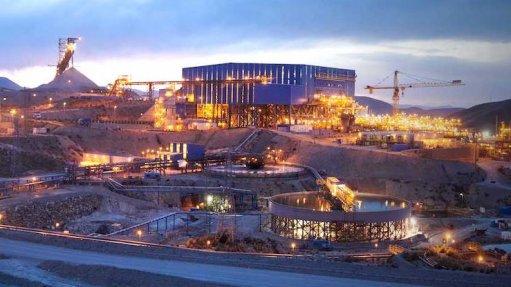

Company Announcement - With the looming threat of load shedding in South Africa and regular disruptions across the rest of the continent, reliable backup power generation solutions are becoming increasingly important in ensuring the long-term sustainability of the rapidly-developing African mining sector. An innovative range of fully-integrated power generation solutions will be displayed at the 2015 Mining Indaba by Cummins – a global leader in the manufacture, sales and servicing of diesel engines and related technology. Mining Indaba is one of the largest mining investment conferences in the world, and the largest event of its kind in Africa.

This year’s event is being hosted at the Cape Town International Convention Centre from 9 to 12 February 2015. Cummins Power Generation Director Kenneth Gaynor highlights that Mining Indaba 2015 will assist in giving a better understanding of the solutions that Cummins can provide. “Mining Indaba 2015 will host some of the world’s largest mining companies, as well as world renowned macro-economists and industry experts. This serves as the ideal platform for us display our unrivalled capabilities, while participating in discussions and sharing ideas which can help to improve and grow the mining industry in Africa,” he explains.

Cummins PowerGen is a world leader in the design and manufacture of pre-integrated generator sets, ranging from 8 kVA to 3300 kVA. The division is able to meet all African mining projects' energy needs, including; continuous, prime, peaking, standby, cogeneration or a complete turnkey power plant. All major components including engine, alternator, transfer switches and control systems are designed and manufactured according to the highest standards of quality set by Cummins.

Gaynor adds that mining operations across Africa can lower their fuel costs and minimise their impact on the environment with the new range of HHP QSK95 Series generator sets, which are Cummins PowerGen’s most powerful diesel generator sets to date, offering up to 3.5 MW 60 Hz and 3.75 MVA 50 Hz. “They are engineered with the highest kilowatt per square foot ratio in their class, resulting in a smaller footprint that achieves a 20 percent improvement in power density.” The durable and robust QSK95 Series generator sets are ideally suited for mining, oil and gas, or any project where harsh conditions, challenging environments and the demand for reliable, continuous remote power exist. The QSK95 Series generator sets are also engineered to deliver reliable, mission critical power protection without interruption. Fewer maintenance requirements, longer service intervals and 25 000 hours to major overhaul make these generator sets ideal for prime power applications. The generator sets accept 100 percent of rated load in a single step, and are ready to accept facility load in less than 10 seconds. With a smaller footprint, the QSK95 Series requires less space to install and, in multiple-generator set applications, fewer generators are required to achieve the necessary power output.

Official launch of groundbreaking filtration technology

Cummins’ latest advancement in Nanonet® technology is the Fleetguard FH239 Series Industrial Pro diesel fuel filtration system and all-in-one fuel/water separator, which will be officially, launched locally at the 2015 Mining Indaba, following successful trial runs at mine sites. Cummins Africa Technology training manager Tim Haywood notes that the Fleetguard FH239 Series Industrial Pro has been proven to dramatically extend oil drain intervals, improve overall efficiency and decrease the total cost of ownership on a number of leading OEM machinery and equipment that operate in harsh South African mining conditions. “As of October 2014, independent laboratory tests on fuel analysis revealed that the FH239 filtration system meets internationally-recognised ISO 4406 certification. Efficiency is measured in terms of a Beta (β) ratio. The Beta ratio for parts FS53014 and FS53015 is greater than β1000 @ 7 micron (µ,) compared to the FH234 series with a Beta ratio of β250 @ 7 µ,” he explains.

During local testing, the tank level cleanliness started at 22/21/17 – measured at 4 µ, 6 µ and 14 µ respectively. After installing the FH239, the fuel level cleanliness readings were 13/10/6. Following a second stage of filtration using the FF5782 system, the readings reached 10/9/5, which means considerably cleaner fuel, which ultimately results in a longer expected lifespan of the fuel injection system. The FH239 also provides easy maintenance with its self-priming pump. By simply spinning off the cap, users can pour in fuel and restart the engine with clean, filtered fuel. The clear cover tells users when not to change their filter and offers a window into the system to see fuel condition and flow. This is patented ‘Seeing-is-Believing’ technology, which offers superior effectiveness in removing water and contaminants from the fuel system. Filters can be changed within a matter of minutes. Dry filter changes can be completed by simply draining fuel below the collar and replacing. The design also ensures that there are no hazardous fuel spills either.

Tried-and-tested engines

Mining machinery is only as reliable as the engine that powers it, which is why the Cummins range of engines has steadily gained strong market share in the African mining industry. Cummins has developed a strong presence in the mining sectors of South Africa, Angola, Botswana, Ghana, Mozambique, Nigeria, Namibia and Zambia. The Cummins brand of engines has consistently gained popularity with numerous mining houses operating on the African continent in various mining applications, including; gold, diamond, copper, iron ore and coal, due to the fact that the high horse power engines have been proven to withstand the harsh operating environment over time.

The two most popular series of Cummins engines that are used in the African mining industry, on display at the 2015 Mining Indaba, are the QSK and the K series engines, which power a wide range of mining equipmentsuch as wheel loaders, haul trucks, excavators and large loading shovels.

The range of QSK MCRS series engines are among the most environmentally friendly in the world, and are fully compliant with TierII low emission standards set out by the American government’s Environmental Protection Agency.

Compliance with EPA specifications ensures that Cummins QSK series engines minimise environmental damage by generating clean power, while increasing fuel efficiency and lowering operating costs, without affecting the power of the engine.

EPA laws are becoming a world standard and, although the specifications are not a legal requirement in a number of African countries yet, it places local fleet owners and mining houses in the perfect position to stay one step ahead of the game by adopting the new technology at an early stage.

Exhibition details

Cummins will be exhibiting at Stand 3604 in Hall 4 throughout the duration of the event. For more information on the 2015 Mining Indaba, visit www.miningindaba.com

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation