Platinum group considers future mine mechanisation

Platinum mining, refining and marketing company Impala Platinum (Implats) tells Mining Weekly that it is investigating the mechanisation of mining activities as a sustainable way to continue mining operations in the future.

The company, which produced 25% of the world’s platinum in 2012, reports that mine mechanisation is being considered for three new mine shafts in Rustenburg, South Africa.

Implats is looking extensively at how to mechanise the vertical No 16, 17 and 20 shafts. The No 20 shaft is ramping up to production, while No 16 was recently commissioned and No 17 is approaching the end of its sinking phase. The company is also investigating opportunities to stope with mechanised equipment.

“We have elements of mechanisation, but full mechanisation could possibly only be accomplished in 20 years’ time,” says Implats group executive Martyn Fox, adding that, owing to a volatile period in platinum production, the company is restricting investment to existing projects required to maintain current production levels.

“Currently, we are not going overboard with new technology, but rather focusing on improving the operations that we already have by making them more efficient.”

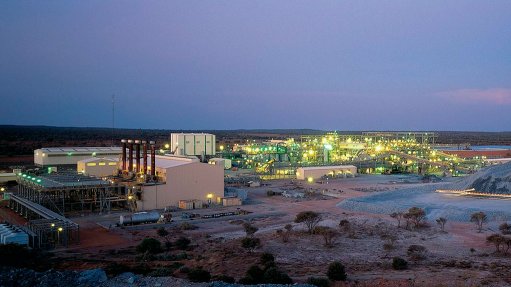

The company claims that its concentrator and smelter plants are on par with other plants of its kind in the industry, while its refinery is cutting edge. “Our refinery is world class,” says Fox, adding that it is probably the most advanced precious-metals refinery in the world.

The actual process used at the refinery is what makes it world class, notes the company. The refinery operates as a proprietary process that involves unit processes, which were researched and developed in the early 90s and then piloted and constructed in the mid- to late 90s.

“This technologically advanced refinery means short processing times, better recoveries and lower costs for us,” says Fox.

While the company has a full-time research and development department at its refining operations, it is predominantly focused on optimisation and efficiency improvements.

Going forward, Implats is looking extensively at mechanisation in all its new mines. “Mechanisation is a very emotive issue because, in all likelihood, there would be a shift away from unskilled jobs to higher skilled jobs. These jobs would come from the development, fabrication, operation and maintenance of the machinery,” says Fox.

He adds that the change management models and the strategy that the company is using for mechanisation are more focused on using mechanisation to bring new mines into production.

“As practical as mechanisation seems, the conversion of existing mines into mechanised mines is very difficult and that would not be a starting point for us,” Fox says.

Meanwhile, the platinum industry is experiencing a slump, owing to the drop in commodity prices. “The industry is currently experiencing a challenging environment and the platinum industry is not producing what it could,” he adds, noting that labour unrest is another challenge facing the industry.

Fox notes that most of the platinum industry is driven by international car markets, which use platinum-group metals (PGMs) in the production of emission-limiting autocatalysts.

“There is not a great deal of growth at present. The European automotive market, which is diesel dominated, predominantly uses platinum and is, unfortunately, stagnant. The US market, which is more dependent on petrol and palladium as a catalyst, is, how- ever, registering some growth,” he says.

Implats notes that another major challenge is that autocatalyst companies are using palladium as a substitute for platinum, since it is currently less expensive. However, it requires higher quantities to have the same emission-reducing ability. “Previous shifts toward greater use of palladium have resulted in increased palladium prices and a gradual return to platinum after a while,” notes Fox.

“Thrifting has also become a trend in the industry, as companies are attempting to get the same results and performance from less platinum,” says Fox, adding that employing thin layers of PGMs using nanotechnology means lower costs for companies. In the long term, the company notes that fewer units of PGMs might be required, but tighter emission legislation will negate drastic reductions.

Implats notes that the platinum industry is hampered by financial constraints, owing to reduced revenues from metal sales at cyclically low commodity prices .

From a mining perspective, the industry is struggling with labour relation issues and productivity levels.

“It is a very cyclical industry in which we work and it is not the first time that we have experienced this,” says Fox.

He highlights that, to sustain the industry, commodity prices need to rise before capital can be spent and reinvestment made in operations.

Trends and Technological Advances

“As a result of some of the challenges facing the industry, there is renewed interest in taking investment risks involving the introduction of new technologies, when companies can afford to fund it,” says Fox.

He adds that, when funding becomes constrained, one of the first things to drop down the priority list is the research and design for new developments. “Government initiatives leveraging collaborative private- and public-sector funding are useful in this regard,” says Fox.

The company has an innovations and technology forum, but it currently concentrates on the mining sector, since the mining division of the company comprises about two-thirds of its costs.

Meanwhile, the company places a great deal of importance on the health and safety of workers at its mining operations and notes that mechanisation is a way of reducing potential injuries sustained during operations.

“We are interested in using mechanisation to get people away from the mining face, which is where workers are at greatest risk to injury,” says Fox, who adds that ensuring safety at mining operations is the company’s primary goal.

“Mechanisation not only means that the health and safety of workers will be significantly enhanced, but it will also encourage lower costs in the long term as well as increased productivity,” concludes Fox.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation