Plan under way to prevent equipment failure, ensure reliable analytics

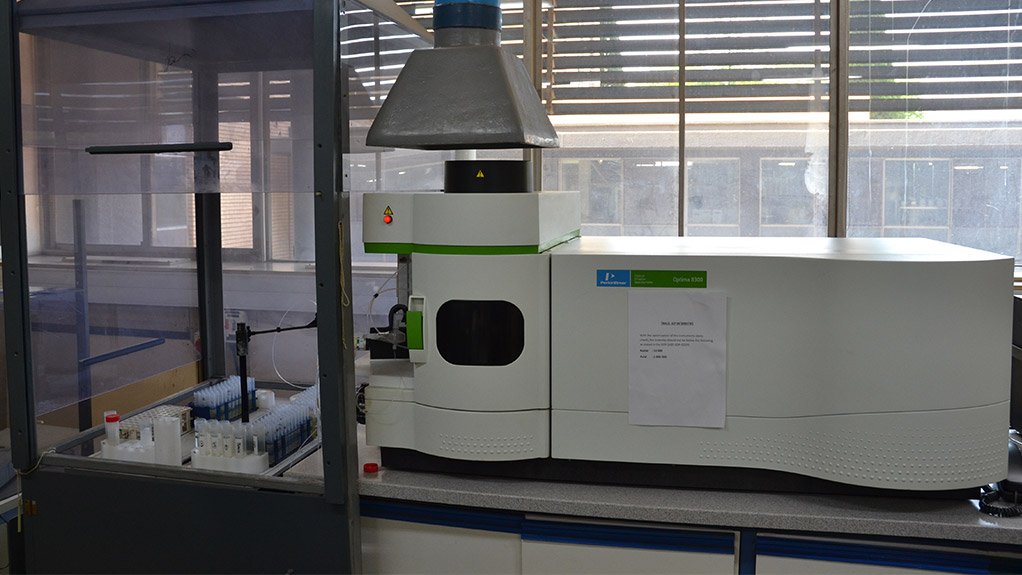

ANALYTICAL INSTRUMENT Mintek’s Analytical Services Division’s new inductively coupled plasma mass spectrometry instrument, similar to this one, will be commissioned at the end of January

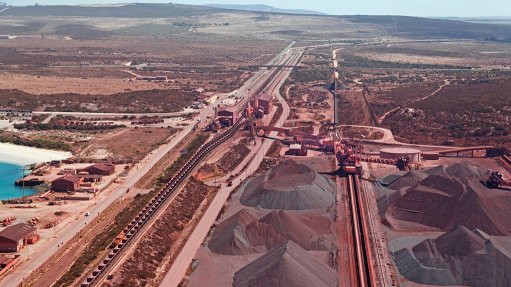

EQUIPMENT RENEWAL EMPHASIS Mintek is aiming to timeously prioritise the early replacement of essential instruments, which was previously done at random

State-owned council for mineral technology Mintek is implementing a five-year “grand plan” to replace existing equipment in its Analytical Services Division, in Randburg, thereby mitigating the risks of breakdowns and unavailability.

Mintek Analytical Services Division manager Joe Baloyi tells Mining Weekly that some new instruments have been acquired, while tenders have been issued for the procurement of other technology.

He says, previously, analytical instruments were replaced randomly and only once they had reached the end of their expected life span. This made the instruments less accurate and prone to frequent breakdowns, thus hindering Mintek’s ability to conduct comprehensive analysis on samples.

The new equipment replacement plan was draughted in 2013 and aims to prioritise the early replacement of essential instruments. It also assists in the procurement phase by providing timelines for orders to ensure old instruments can be used until they are replaced with new ones. Therefore, production levels are maintained between the decommissioning of old instruments and the commissioning of new instruments.

Baloyi says there is currently a tender out for the acquisition of a new X-ray fluorescence (XRF) spectrometer, which is used to routinely analyse rocks, minerals, sediments and fluids. It operates on wavelength-dispersive spectroscopic principles that are similar to an electron microprobe.

“Our existing XRF instrument is due for replacement in the next six months,” he adds.

As part of the five-year plan, Mintek’s Analytical Services Division has received a new inductively coupled plasma mass spectrometry (ICP MS) instrument, which is currently in storage and due to be commissioned at the end of January.

The commissioning date takes into account the highly sensitive nature of the new ICP MS instrument, as Baloyi explains: “We chose to install and commission it only once the renovations [under way at the Analytical Services Division] are complete, as any dust, dirt and subsequent excessive moving of the instrument will decrease its analytical capabilities and might lead to unnecessary failures.”

The ICP MS instrument will be used for low-level analysis. Baloyi says, on average, a laboratory can report on particle levels as low as ten parts per million (ppm) to 15 ppm, but the new ICP MS instrument will allow for sample analysis of below 10 ppm to about ten parts per billion.

Industry Trends

A lack in confidence is emerging in the platinum-group metals (PGMs) sector, as a result of German car manufacturer Volkswagen’s (VW’s) recent emissions scandal, where selected diesel VW vehicles emitted more toxic fumes than officially stated by the company, thereby circumventing several countries’ emissions standards and regulations.

Platinum is a core component of vehicular exhaust systems fitted with catalytic convertors for the removal of toxic pollutants in exhaust fumes.

The VW emissions scandal is affecting quite a few companies that are associated with PGMs, which has led to consumers losing confidence in the industry as a whole, notes Baloyi.

This is expected to lead to fluctuations in demand for PGMs that will, in turn, impact on platinum miners and processers. “When production at mines wanes, this has a knock-on effect further down the supply chain and impacts on analytical services companies, such as Mintek.”

Meanwhile, he also notes a shift from conventional analysis processes to those orientated towards environmental protection, owing to pressure from government and industry in general.

“Because of the environmental responsibility aspect, many companies are investigating the impact of their products and processes on the environment. In the case of consumable products, the end-product is mostly sent to landfill as refuse and poses a contamination threat to groundwater sources.”

Baloyi states that this requires laboratories to conduct low-level tests to identify significantly more particles in their products.

“There [also] is currently much movement towards urban mining, which is the act of recycling various items of refuse or scrap, such as plastics, paper and electronics, which include cellular phones, televisions and computers.”

In the case of electronics, the most valuable recoverable items are gold and other metals, which are then melted and, subsequently, returned to the market as reusable commodities, creating a previously unavailable stream of certain commodities at a lower cost than the commodities provided using conventional mining methods.

“Mintek is embracing urban mining. When certain commodities, such as PGMs, perform poorly on the market, we focus on analysing other commodity streams, such as those derived from urban mining, to maintain work levels and expertise,” says Baloyi.

Meanwhile, Mintek’s Analytical Services Division is shifting away from offering only analysis to include training services, enabling the division to create a secondary source of revenue.

In addition, the division provides reference materials. “Should a client want to have material certified, the material is sent to Mintek, where it is processed and verified according to its composition, packaged into units to the client’s preference and returned to the client as certified reference material,” Baloyi outlines.

This, he says, provides another source of income and jobs amid challenging times in the mining industry.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation