OEM-status provides significant competitive advantage

COAL PROCESSING Isogate knife gate valves used in a coal application

MECHANICAL PINCH An Isogate mechanical pinch valve with Linatex rubber wear liner

ISOGATE VALVE Isogate valves and Linatex hoses, along with all Weir Minerals products offer a complete solution to customers

Being an original-equipment manufacturer (OEM) gives slurry-equipment company Weir Minerals Africa a significant competitive advantage in the valves marketplace, says Weir Minerals valves product manager Kobus Steyn.

He states that the company manufactures and distributes its own products, as opposed to only being a distributor of other’s products, adding that it has intstalled its Isogate and BDK valves across numerous industrial sectors.

“We have won a number of projects where we have supplied the valves, actuators and full hydraulic systems, designed by Weir Minerals’ engineers. We have also supplied complete packages to engineering procurement contractors and end-users that include butterfly, ball and check valves, as well as control and safety relief valves,” says Steyn.

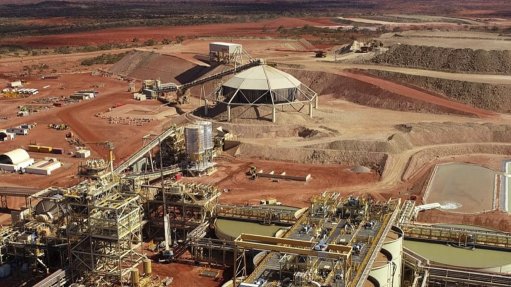

He says Weir Minerals’ Isogate valves are ideal for abrasive applications in mining and minerals processing, adding that Isogate slurry valves operate in some of the harshest and most demanding environments globally.

Applications of these valves range from use in the processing of base metals, such as copper, nickel and iron, to precious metals and gems, such as gold, silver, platinum and diamonds, as well as industrial minerals, such as phosphates, talc, kaolin, silica and clays.

Isogate slurry valves provide a cost-effective solution for on/off, throttling and reverse-flow controlling of flowing media in industrial processes that involve abrasive or corrosive materials. These range from sand and gravel to dredging, water and wastewater, food collection, preparation and processing, coal-fired power plants, pulp and paper mills and shot and sand blasting equipment manufacturers.

Steyn comments that Isogate slurry valves are so successful in these diverse applications because they feature ease of maintenance and low total cost of ownership as the main design criteria.

“Conventional valves are only designed for liquid service and therefore seldom produce satisfactory results when applied in abrasive and/or corrosive slurries,” notes Steyn.

Typical problems with conventional valves include rapid wear of valve seats and liners, sticking and leakage to the atmosphere during operation.

Meanwhile, Isogate slurry valves can operate under wide pressure and temperature ranges, while sleeves are available in a variety of materials, from natural rubber to ethylene propylene diene terpolymer, nitrile or neoprene. A unique feature of these valves is that Weir Minerals can offer its proprietary abrasion resistant Linatex premium natural rubber liners.

Isogate mechanical pinch valves use a flexible rubber-lined pinch sleeve that is collapsed between two mechanical bars for accurate modulating control, positive closure and drip-tight shut-off. The inside diameter of the pinch sleeve is full-line size for maximum throughput and minimum pressure drop.

Isogate pneumatic pinch valves are pneumatic or hydraulic actuated enclosed body pinch valves ideal for remote operation using typical plant air and not requiring auxiliary cylinder operators. These valves use flexible rubber-lined pinch sleeves and pinch liners enclosed in robust cast metal bodies that collapse when plant air or hydraulic pressure is applied.

Isogate heavy-duty slurry knife gate valves combine a low maintenance design with a range of materials for diverse applications. The particular focus here is abrasion resistance, says Steyn.

“For example, the Isogate WB Series features a robust design and rugged, heavy-duty construction for increased reliability and wear life, together with ease of maintenance and cost effectiveness in a lightweight, compact package.”

Meanwhile, Weir Minerals’ BDK valve range is ideal for general and specialised industrial applications, Steyn says.

These range in applications from power generation to oil and gas, petrochemicals, steel, fertiliser, pharmaceuticals and water treatment. The BDK valve range encompasses ball, butterfly, gate, globe and check valves, as well as diaphragm, knife gate and plug valves.

Weir Minerals states that valves form an integral part of its total solutions package for the mining and minerals processing and general industrial sectors.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation