New copper proficiency testing scheme for mining laboratories

TESTING PROFICIENCY Mining industry laboratories can benchmark their analyses with Qotho’s new copper proficiency testing scheme

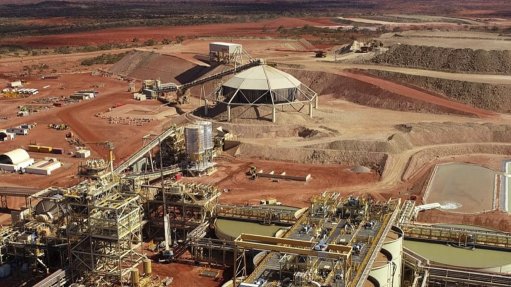

MINING LABORATORY Mining laboratory services provider Tramecon aims to complete the installation of a container laboratory for the Kinsenda copper mine in October

In response to requests from mining laboratories, mining laboratory quality control services provider Qotho Laboratory Services will launch its new copper and nickel proficiency testing schemes this month, with additional plans to launch a zinc proficiency testing scheme by year-end.

Qotho, a subsidiary of mining laboratory services provider Tramecon, focuses on providing interlaboratory and proficiency testing schemes for different minerals and commodities, explains Tramecon MD Hannelie de Beer. She adds that Qotho is already running manganese and chrome proficiency testing schemes.

“The primary aim of the copper proficiency testing scheme is to enable mining production and certification laboratories to monitor their performance against other industrial laboratories, thereby ensuring the continuous improvement of the quality of their analy- tical data,” she says.

The proficiency testing scheme involves providing samples of copper concentrate, which are milled, crushed and homogenised, to the participating laboratories, which will test and analyse these metal concentrate samples and report their results and methodologies used to Qotho.

Using statistical techniques and Prolab Plus statistical software, Qotho analyses the results and performances of the participating laboratories and issues a report to the participants, who can subsequently compare their results with those of the other laboratories, explains De Beer.

She points out that Tramecon identified the need for proficiency testing schemes in South Africa’s mining and commercial laboratory sector in the last few years, which is why it created Qotho as a subsidiary.

“This testing scheme will act as a benchmark, providing laboratories with a means of assessing the accuracy and comparability of their metal ore test results against those of peer laboratories,” De Beer says.

At least ten laboratories from South Africa and other African countries, including Zambia and the Democratic Republic of Congo (DRC), will participate in the pro- ficiency testing scheme, while quality inspection houses, such as ALS Inspection Division, which provide inspection services on the quality and quantity of commodities, have also indicated their interest in participating.

The scheme will run every two months to supply updates to the participating mining and ind- ustry laboratories.

Quality Assurance

De Beer points out that, as all copper mines aim to recover as much of the commodity as possible, they rely on mining laboratories for accurate results throughout all the mining and mineral processing phases.

From these results, mining companies can make critical, informed decisions about the viability and adequacy of current pro- cesses and whether specific control adjustments need to be made. De Beer further stresses that the benchmark, which the testing scheme provides, will hopefully enhance client confidence in mining industry laboratories and in mining companies’ in-house laboratories.

“The proficiency testing scheme is a significant tool to provide mine geologists and metallurgists with the confidence that the daily results from laboratories are accurate and meet the relevant standards. If the results lack the necessary quality standards, Qotho can help improve these standards by auditing the processes and highlighting key problem areas.”

Qotho technical director Nhlanhla “Lucky” Mamba adds that several mining companies have previously outsourced the services offered by their in-house laboratories to external laboratories and some still do, owing to the lack of sufficient and trustworthy results produced by in-house laboratories.

“This results in a loss of credibility for in-house laboratories, which comes at a high cost, as mines have to use external services,” he says.

Mamba also highlights the negative knock-on effect of time delays when samples are sent from mines to external industry laboratories for analysis, since this jeopardises a mining company’s ability to make swift decisions about plant operations, thereby affecting revenues.

However, with the benchmark opportunities that the proficiency testing schemes will provide, quality issues can be addressed more swiftly to improve process flows at the mines, says De Beer.

“The proficiency testing scheme is a quality function with a positive financial implication,” she adds.

De Beer further points out that, the more in-house mining laboratories’ analysis and testing methods improve, “the better the mines and their processes will perform, which will improve their profitability”.

As the proficiency testing schemes are not bound by geographical boundaries, De Beer hopes to pique global interest and increase participation in these schemes, which may result in the participation of Russian nickel mines and South American copper and nickel mines, among other international developing projects.Laboratory Installations

Meanwhile, Tramecon is proceeding with plans to complete the installation and commissioning of a multimillion-rand container laboratory, at the DRC’s Kinsenda copper mine, in Katanga province, in October.

The laboratory comprises four containers designed by Tramecon, which will also oversee the container conversions and the acquisition of laboratory testing equipment, spares and consumables. The project includes training mine staff to use the laboratory services, says De Beer.

Mining company Metorex, which owns the copper mine, awarded the tender to Tramecon at the end of last year.

De Beer notes that the bulk of Tramecon’s work to date, which involves supplying mining laboratory services and equipment to mines, has occurred in the Zambian Copperbelt, with three laboratories having been commissioned and installed since 2007.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation