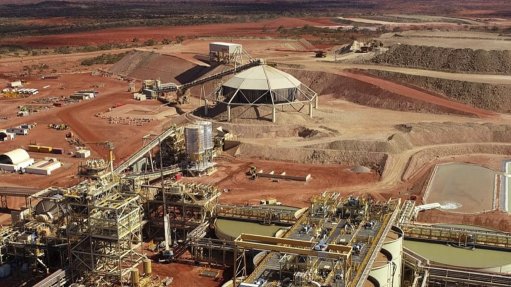

Murray & Roberts Cementation Wins Palabora Vent Shaft Contract

Murray & Roberts Cementation, Africa’s leading mining contractor, has been awarded a contract by Palabora Mining Company for a 1,200 metre deep ventilation shaft.

The shaft, with a lined diameter of 8,5 metres, will reach a final blind sink depth of 1,190 metres before a drop raise takes it to its final depth, according to Braam Blom, project executive at Murray & Roberts Cementation.

“The duration of this project is expected to be just over three years,” says Blom. “After mobilisation, site establishment and surface civils have been completed, we expect to conduct pre-sinking until the end of 2019, with the use of our special shaft sinking gantry to a shaft depth of 65 metres.”

A surface headgear and winder installation will then be constructed from January to March 2020. This will facilitate the slow sink to 200 metres and the main sink until February 2022. Canadian shutter and lining methods will be employed. The team is expected to conduct shaft stripping by mid-April 2022 and to dis-establish the site by the end of May 2022.

“There will be no stations or other excavations required, so this will help keep the team in a sinking cycle and optimise production levels,” he says. “We will run full calendar operations (Fulco) with 12 hour shifts and cycles of five day shifts, five night shifts and five shifts off.”

A relatively small labour force of 123 people is planned for steady main sinking conditions, with some sub-contractors conducting surface piling and civil works for the winder, headgear and other site construction. Shaft drilling itself will be done with two twin-boom Komatsu shaft drill rigs, and mucking by a Komatsu excavator with close to a ton of loading capacity.

“Ground conditions are expected to be a challenge in some areas, as profiled from the cover and core drilling,” says Blom. “However, we have various ways of reducing the risk and downtime during these intersections – such as keeping the shaft lining as close as possible to the shaft bottom.”

Blom highlights that the company continuously improves performance based on lessons learnt from its wealth of previous projects. This allows a constant focus on securing safe, sustainable and efficient shaft sinking, to deliver on the completion target.

Among the unique benefits offered by Murray & Roberts Cementation is its world class training facilities at Bentley Park, including mock-up shafts where employees and trainees build up first-hand experience of operating conditions underground.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation