Metso renovating KZN foundry to meet growing mining-sector demand

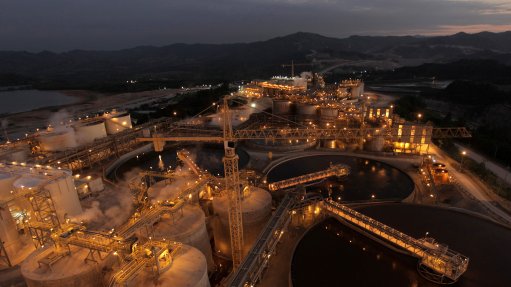

ISITHEBE FOUNDRY Through the renewal of the Isithebe foundry, Metso will improve capabilities to deliver high-quality, heavy-wear parts

Industrial company servicing the mining industry Metso is investing €3.5-million in crusher wear parts manufacturing in Africa by renovating a second melting furnace at the Isithebe foundry, in KwaZulu-Natal, to meet growing demand from the mining industry for such components.

The investment will enable the company to improve its quality to enable large crusher wear parts castings and ensure the availability of Metso’s heavy crusher wear parts globally.

Metso mining crusher wears director Joni Meronen says this investment will ensure that Metso meets customers’ needs: “Through the renewal of the foundry, we will improve our capabilities to deliver high-quality, heavy-wear parts.”

The foundry will manufacture wear parts for the Nordberg MP2500 series of cone crushers (which is claimed by Metso to be the world’s largest cone crusher), as well as for Metso machinery and third-party machinery using primary gyratory wear parts, making full use of the latest manufacturing technologies.

The first product deliveries from the new furnace are scheduled for May 2019. During the renovation project, production of castings will continue as usual at existing facilities.

The renovated foundry will be built to Metso’s strict sustainability and quality principles, as well as international standards.

Metso crushing and screening wears senior VP Jose Perez says the company is the only supplier providing a full portfolio for comminution, from spare and wear parts to equipment and service. “This investment is part of our development agenda to execute our commitment to ensuring availability and reduced lead times for customers.”

The Isithebe plant is part of Metso’s global foundry network, consisting of foundries in Ahmedabad, India; Přerov, in the Czech Republic; Quzhou, China; and in Sorocaba, Brazil.

Isithebe foundry director Thando Makhoba says sustainability is of the utmost importance to Metso, with the company developing its operations in a safe and sustainable manner, in close consultation with local communities.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation