Work on ventilation shafts project at Palabora copper mine set to start soon

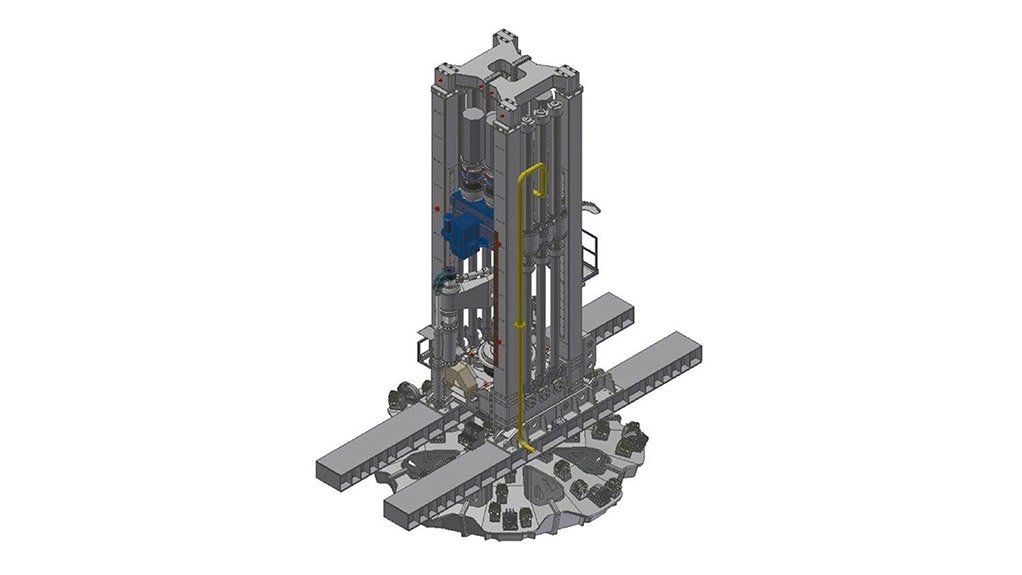

RD8 RAISEBORING MACHINE Master Drilling designed and built the machine specifically for the Palabora Mining Company project

RD8 RAISEBORING MACHINE Master Drilling designed and built the machine specifically for the Palabora Mining Company project

Raiseboring and drilling services group Master Drilling will soon embark on the civil construction of a shaft collar on the first of two ventilation shafts for refined-copper producer Palabora Mining Company (PMC) at its mine in Limpopo.

“We anticipate completing construction of the first shaft during the fourth quarter of 2016,” Master Drilling executive director Koos Jordaan tells Mining Weekly.

The company was awarded the three-year construction contract in December 2014 for an undisclosed amount.

Jordaan says piling works will be undertaken on the circumference of the excavated area and a foundation for the shaft will be constructed during the civil construction phase of the project.

“On the foundation, we will drill a small 40.6-cm-diameter hole, which will be drilled through to a holing point underground. “We will then drill the pilot hole into an existing tunnel underground and then hook up a reamer head, which will be pulled up to the surface,” he explains.

Jordaan highlights that the company designed and built the RD8 raiseboring machine specifically for the PMC project, which entails the construction of two 6.1-m-diameter ventilation shafts, each with a “record-breaking” depth of 1.2 km.

He avers that the technology of the RD8 machine is unique, as it operates about four times faster and is significantly cheaper than the conventional blind-sinking technologies. The machine requires only two personnel per shift to operate the equipment.

Jordaan points out that the employees will operate the machine from the safety of an above-ground control room.

“Ultimately, this ground-breaking raiseboring machine is key to pursuing deep-level, large-diameter shafts in future projects,” he states.

Jordaan also notes that the company’s remote-operated shaft support (ROSS) unit and inspection device will be used to line the shafts, either during or after the raise- boring process.

“The ROSS system can line up to a depth of 1.5 km underground and the inspection device can scan the geometry of the excavation and identify the lithology. This is important to determine the stability of the shaft during or after construction.”

Lonmin Project

Jordaan points out that, in January, Master Drilling completed the 1 km Rowland shaft project at platinum miner Lonmin’s Marikana mine, in the North West, using similar technology.

The Rowland shaft project differed from the PMC project in that Master Drilling did not apply the same secant wall piling civil construction method and the ROSS system was not used.

Jordaan explains this was because the fresh rock of the Rowland shaft project was only about 3 m from the surface and there was not much unconsolidated ground on the surface.

“Therefore, the shaft’s foundation did not have to be constructed using piles and no remote support work was needed either.”

Jordaan says that the Rowland shaft project was accomplished within budget and on schedule, with no incidents, accidents or damage to property.

“The project was a huge success and the company employed three local community members as part of our drilling crew. “These new crew members have been retained, as they have proven their competence by delivering work that is of a high standard, and which complies with the company culture,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation