Holistic approach needed to effectively implement new technologies in mining

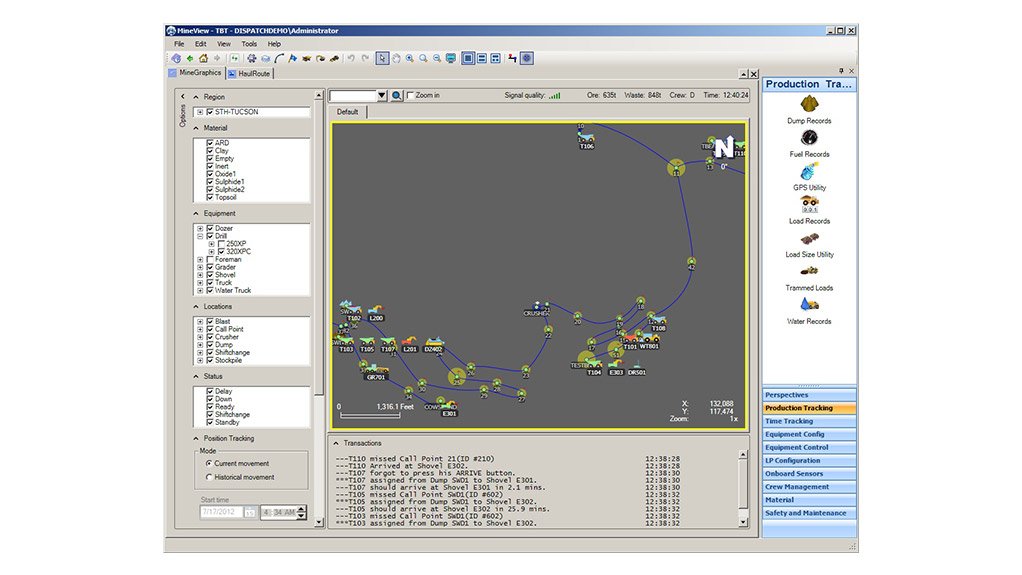

INTRICATE ENDEAVOUR The implementation of new technologies and applications has in many cases created overly complex business processes

GARY LANE Mining should be viewed as a system because a mine is a system of interconnected activitie

Photo by Duane Daws

Smart innovation and technology in mining will not deliver the quantum change that is required unless a holistic business enterprise architecture view is taken and the mining business is redesigned along a path of digital maturity, says local enterprise software developer NxGN CEO Gary Lane.

He states that the running of mining companies is becoming significantly more complex owing to mechanisation, which has strengthened the interconnectedness of mining activities.

Lane also notes that multiple task dependencies between systems and data have resulted in a “spider web of integration” that has been organically built from the bottom up. He further highlights that the implementation of new technologies and applications has in many cases created overly complex business processes.

“There is also no clear understanding of the underlying data definitions and structures, which means that companies require analysts to access and make sense of the data,” Lane points out.

He argues that the role of information technology (IT) in business has become blurred, as IT has in essence taken ownership of the business processes, data and business applications.

“I feel that this should be owned by business and not IT, as, in instances when the data is not correct, it has become very easy for business to blame IT for the systems it has created,” Lane states.

He says that business processes were “forced” on business by IT and have now become the standard business process.

“I was building a new mine plan solution with [infrastructure software manufacturer] Bentley Systems and the biggest obstacle that I faced was that technology would allow us to do mine planning completely differently and the computers would allow for a lot of the manual tasks to be performed automatically. However, the change management around modifying how people did their jobs was a major challenge,” Lane reveals.

He says they could have created the “most amazing technology” but, instead, only incremental changes were made in the end.

Lane explains that this was because mine operators wanted to perform the same functions and press the same buttons that they had been pressing for the past 15 years, despite the fact that there were certain functions and responsibilities that were “totally redundant” because of technological developments.

In essence, he says, the mine operators wanted to “panel-beat” the technology to meet the business process that had been designed – or forced on business – over the years, owing to technological inefficiencies.

Additionally, Lane notes that a lot of data noise has developed, which creates a situation where there are vast amounts of “rich data but poor information”. He believes that this is why IT professionals feel additional sets of real-time dashboards are necessary, as they expect that managers will be able to identify variables and the key performance indicators that need to be managed to increase performance.

“This, however, often results in the ineffective identification and management of the key input metrics, which thereby negatively impacts performance outcomes,” Lane states.

He does not believe that managers even know how to effectively manage the interconnected activities between drilling, blasting, hauling and other unit processes, which all impact on the system throughput of mining.

“Applications and IT are replacing experience, conceptual thinking and problem solving. I have been saying in the past couple of years that people have become box tickers that just follow the process. They are completely reliant on computers completing the task, with little or no understanding of what the system is doing,” Lane laments.

Mining System

Lane says that mining should be viewed as a system because a mine is a system of interconnected activities comprising data, information, business practices, roles and responsibilities, as well as software applications.

He says that these activities need to be supported by an effective “underlying technical architecture”. Companies have to avoid the “working in silos mentality” as they need to develop an integrated view of the system’s performance by evaluating its complete throughput and associated financial metrics, Lane advises.

“I believe that the mining industry needs to develop a standard mining information model to become optimally efficient. The mining industry needs to collaboratively develop this standard model between mining companies and technology vendors.”

Lane believes that this will allow for the standard integration of the best applications to be applied to the business operating model. He adds that the model should be one that allows for the use of scalable, maintainable and sustainable technical integration technology.

Another important role is that of the business enterprise architect, who has the critical role of integrating the business and IT domains into a single system, Lane says.

He holds that, in future, the role of a mine’s GM will be very different from what it is currently.

“GMs currently are essentially people managers. However, in future, I believe that they will need a lot of systems experience because a mine is going to be an interconnection of technologies,systems, information management and data integration,” Lane contends.

Therefore, he says, the mine GM of the future will have to understand the complexities that surround systems because there is likely to be “a lot more automation and a lot [fewer] people on mines”.

Lane was a keynote speaker at the Southern African Institute of Mining and Metallurgy’s recent international symposium on Mine Planning and Equipment Selection, which took place in Johannesburg.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation