Growing hammer range benefits drilling applications

IMPROVED PERFORMANCE The growing RH460 range increases the impact–energy transmission in variable ground conditions

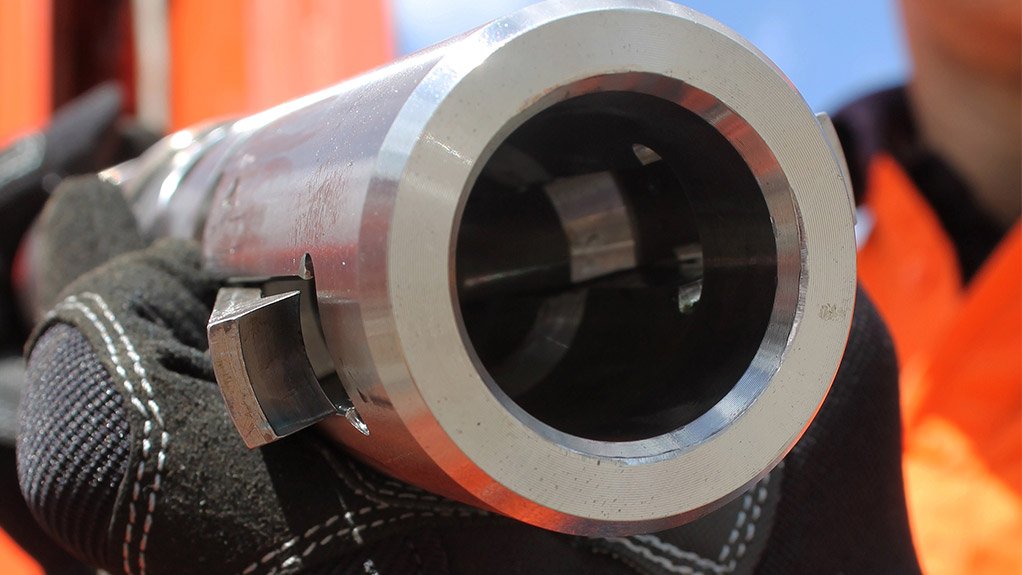

IMPROVED DESIGN The NSU core barrel system features an innovative new design that increases productivity

NOTIFYING THE USER The pump-in overshot features a ball valve indicator, which alerts the operator of positive latching onto the core barrel’s back end

Mining equipment and services provider Sandvik Mining has added six- and eight-inch models to its growing RH460 DTH hammer range, designed to reduce costs, increase penetration rates and prolong the service life of drilling applications on surface mining operations.

The company has also introduced four- and five-inch RH460hp hammers – air-efficient high-pressure models designed to operate at 32 bar to 35 bar. At 35 bar, RH460hp hammers consume less fuel and cost less to operate than similar hammers operating at the same pressure, notes Sandvik.

The high-pressure hammers, an ideal match for the Sandvik DR500-series rigs and the com- pany’s new Pantera drills, feature the same benefits as the other RH460 hammers.

The growing RH460 range increases the impact–energy transmission in variable ground conditions. The range’s enhanced air cycle also improves expansion and compression rates, producing more power while reducing the model’s air and fuel consumption.

Further, owing to developments in the piston design and improved lubrication capabilities, the life of the piston and hammer has dramatically increased for all models that form part of the RH460 series.

Sandvik Mining has devoted a significant amount of research and development work to designing the bearing surfaces to eliminate bending vibrations in the piston.

RH460 hammers also feature a unique V-lock mount system designed to prevent the internal components from moving to ensure reliability and eliminate the need for shims and special assembly tools.

The working principle of the RH460 range ensures that the hammers start up in any direction, making their design well suited for all surface and underground mining applications.

The design of the RH460 series makes the hammers easy to service. The complete high-performance, cost-effective range is designed to use bits with generic shank types.

Meanwhile, Sandvik has introduced a multifunctional N surface and underground (NSU) core barrel system, a first-of-its-kind system that features interchangeable components and offers standard and pump-in applications, in a single system.

The NSU core barrel system features an innovative design that will not only increase productivity, but will also offer a more cost-efficient solution by reducing net working capital and spare parts inventory and ensuring safer operations when handling the system.

“The newly patented iQ-FCV valve provides and maintains a constant alert through sustained high water pressure, assuring the operator that the inner tube assembly has positively latched into the core barrel. “This eliminates mislatches and ensures that valuable time is not lost,” says Sandvik mining core drilling product line manager Chris Daws.

“For better water efficiency, the iQ Valve has been designed to always retain the volume of water in the drill string even in broken ground or dry holes, which is an important benefit in core drilling,” he adds.

Further, the overshot attachment to the wire line no longer requires cable eyes or cable splicing, which makes it easier for maintenance operators to repair units in the field.

A newly designed logic tip on the overshot also allows for the inner tube assembly to be released through an in-hole once the water level has been reached, shortening the release time. The pump-in overshot features a ball valve indicator, which alerts the operator of positive latching onto the core barrel’s back end.

The NSU core barrel system is user-friendly and designed for safer handling operations. The intelligent overshot is automatically latch-locking and latches can be released without fingers being used in potentially high-risk areas.

The core barrel system also features a knuckle joint on the overshot, which allows for ease of handling, particularly in the confined space of underground drilling conditions. Load-rated breakaway safety pins also enable the operator to release the overshot from stuck inner tubes safely.

“The Sandvik NSU and forthcoming H surface and underground (HSU) core barrel systems share the majority of components used in the core barrel head assembly,” says Daws.

“With the interchangeable design for both systems, the NSU core barrel head assembly can be converted into an HSU core barrel head assembly, and vice versa. This will significantly reduce parts and spare parts inventory.

“The new core barrel system is designed for both standard and pump-in applications, which means there is no longer a need to keep different coring tool systems on the shelf. It also reduces the net working capital for the owner,” he adds.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation