Further testing confirms pig iron potential of Baobab’s Moz play

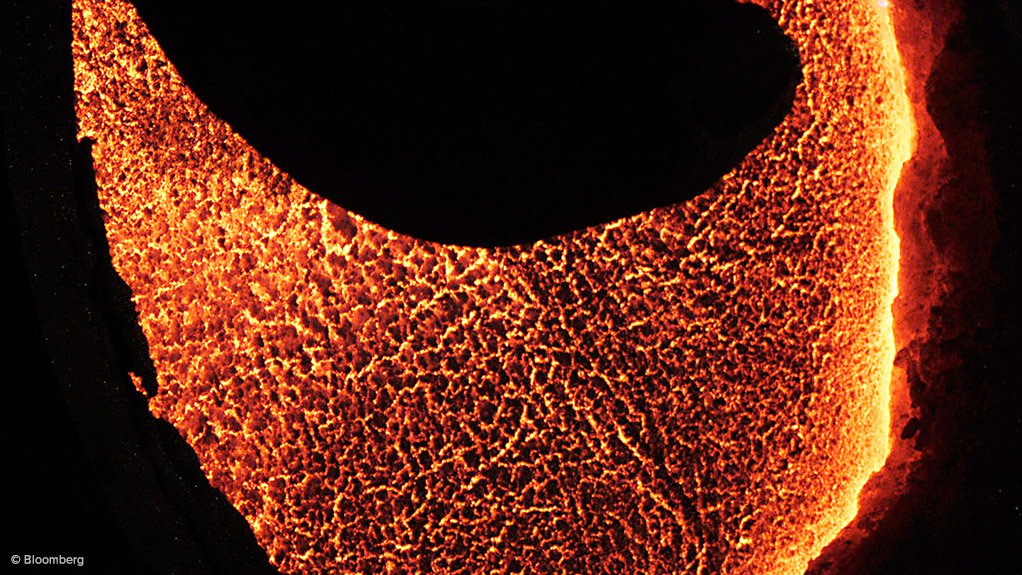

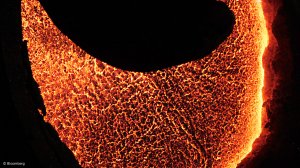

JOHANNESBURG (miningweekly.com) – Mozambique-focused Baobab Resources says a second round of bench-scale beneficiation, reduction and smelting tests of oxidised iron-ore at its project in the Tete province has “again” demonstrated that a low-impurity pig iron product can be achieved.

This second phase of beneficiation and pyrometallurgical studies followed on from prior prefeasibility study testwork on a representative sample of the oxidised iron-ore, which dominated the upper portions of the Tenge resource block and would constitute plant feed for the initial years of operation.

The resultant oxide concentrate reported a grade of 50.1% iron, 0.73% vanadium oxide and 17.6% titanium dioxide at a mass recovery of 67%.

A final iron alloy containing 99% iron was produced after refining and was significantly purer than the specification of a commercial pig-iron product.

Critically, the experiments demonstrated that both titanium and vanadium could be removed from the pig iron into separate slag by-products.

The testwork further confirmed the suitability of three sources of local thermal coal from two commercial operations and one indevelopment project in the immediate Tete project area, achieving at least 85%, and up to 93%, metallisation in the reduction process.

Pilot-scale reduction tests on the bulk samples of Tenge oxide iron-ore, Massamba carbonate and local thermal coal product were scheduled to start this month.

Commenting in a statement on Friday, MD Ben James said the second round of pyrometallurgical results confirmed the company's conviction that a high-quality, low-impurity pig iron could be produced from Baobab's iron-ore resources and locally sourced thermal coal.

“Importantly, the testwork also demonstrates the clean removal of titanium to the slag and that vanadium can also be separately liberated. Larger-scale testwork will clarify the specifications of both by-products,” he said.

Baobab was currently completing a bankable feasibility study at its pig iron and ferrovanadium project, in the Tete province.

The International Finance Corporation held a 15% participatory interest in the project.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation