Fission outlines two-prong strategy as summer exploration campaign is mounted

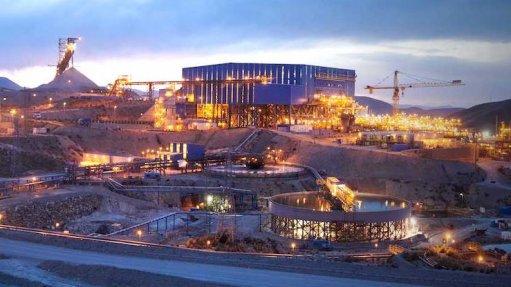

Patterson Lake South, north-west Saskatchewan

Photo by Simon Rees

Damage caused by the Fort McMurray wildfire in Alberta

Photo by Simon Rees

Photo by Simon Rees

Photo by Simon Rees

Photo by Simon Rees

Photo by Simon Rees

TORONTO (miningweekly.com) – Flying into Fort McMurray, Alberta, evidence of the gargantuan forest fire the region suffered in May stretched for miles around: blackened trees, burnt branches and buildings turned to ash.

The blaze occurred during a tough time for the region: low oil prices had led to reduced work in the region’s oil sands, with lay-offs and cuts affecting both direct and indirect employment.

One enduring bright spot, however, has been the opening up of the Athabasca basin’s western side to uranium exploration. A leading project was Fission Uranium’s Patterson Lake South (PLS) project, in north-west Saskatchewan. The company discussed its goals and objectives with Mining Weekly Online on a recent site visit.

PATTERSON PARTNER

PLS was lauded soon after its scale started to become apparent in 2012 and 2013. Fission Uranium had attempted a merger agreement with uranium exploration and development company Denison Mines in the third quarter of 2015, but failed to receive enough shareholder support to proceed.

It then received a 20% buy-in from CGN Mining Company for C$82-million, which was announced at the end of last year and finalised in January.

That tie-up afforded Fission a layer of fiscal protection and the means to continue advancing PLS towards production. It also meant that the company avoided share dilution resulting from repeat equity offerings.

“It de-risks the project having that money because we won’t have to keep returning to the market all the time to raise funds,” Fission chairman and CEO Dev Randhawa told Mining Weekly Online.

He noted that CGN wanted the project advanced towards production within a decade, adding that this would include the necessary baseline studies, metallurgical work and environmental assessments.

“We’ve been doing that for years anyway, so it’s nothing we don't know,” he said, adding that the investment in these areas had to be stepped up because of the drive towards production.

It also means that a twin strategy has evolved as the company wants to keep exploring the PLS property. Fission has to be fiscally conservative to achieve this.

“In the past we might have done about $30-million a year; now we're going to do about $20-million. But that's the right thing to do; we don't want to run out of money and run back to the [equity] market when uranium prices are cheap,” said Randhawa.

He stressed that the company was fully funded for the next three to five years regarding the objectives it had in mind.

WHAT LIES BENEATH

Fission released a National Instrument 41-101-compliant preliminary economic assessment (PEA) for the project on September 3, 2015, outlining a standalone mine and mill operation, with extraction centred on its Triple R deposit (zones R00E and R780E).

Life-of-mine is estimated to be 14 years, with a processing rate of 1 000 t/d and yearly production of 7.2-million pounds of uranium oxide (U3O8). Capital expenditure (capex) is C$1.1-billion, while operational expenditure will average C$16.50/lb. Gross revenue is expected to stand at C$7.71-billion, with net revenue at C$7.12-billion.

Operations will primarily be openpit, with between 75% and 80% exploited through truck-and-shovel methods, according to Fission president, COO and chief geologist Ross McElroy. It will morph into an underground operation once greater depths are reached.

The mine will be separated from PLS by a dyke and berm that is similar in scope to the one constructed for the Diavik diamond mine in the Northwest Territories.

PLS is a veneer, with depths of only 7 m, McElroy explained, adding the overburden continued between 50 m and 200 m until bedrock.

He also stressed the shallowness at which the mineralisation was found, with much of it starting at around 50 m. “The shallowest deposits tend to be the ones mined first because, as a rule, they’re the easiest and most cost-effective operations.”

The dyke and berm will be the most expensive element of capex, with an estimated cost of between C$270-million and C$300-million.

“It’s expensive but it allows for openpit mining, which delivers inexpensive operating costs,” said McElroy, noting it would also deliver greater economies of scale compared with underground operations.

Much of the berm will comprise overburden sourced from the land-based R840W and R600W zones, helping reduce costs. “However, that wasn’t factored into the [PEA] because we don’t have resource yet for R600W, while R840W had yet to be discovered,” he noted.

SUMMER SPECIAL

The company’s C$13.3-million summer drilling campaign is under way, with the rigs declared fully operational on July 7.

The work will comprise 52 holes for around 15 200 m drilled. This includes 36 holes to grow the R840W and R1620E zones, located respectively at the western and eastern extents of the main 2.58 km mineralised trend.

The company announced results from initial holes on July 18 – three from R840W and three from R1620E. It noted that high-grade mineralisation had been drilled at R1620E, expanding the zone 15 m west towards Triple R.

Hole PLS16-485 at R1620E is a highlight, intersecting 35 m total composite mineralisation that includes 7.1 m at more than 10 000 counts per second.

McElroy noted that it was too early to tell if R1620E would change the parameters of the envisaged openpit.

Cost savings and efficiencies had also been sought. For example, Fission used reverse-circulation (RC) drilling to penetrate overburden and then completed the work with core drilling.

Greater use of RC drilling reduces costs because it is less expensive than core drilling.

“On our trend everything is up near the top, which is why the RC rig can work in those cases,” added Ross.

Fission has also initiated a geophysics campaign and a two-dimensional marine seismic survey for the summer season, looking for alterations and geochemical tell-tale signs.

Tied to its dual strategy, the company wants to explore other areas on its property, with 16 holes to be drilled away from the main zone, focused on targets to the south and south-west. That includes Forest Lake, which neighbours PLS.

However, a forest fire has prevented a closer look at Forest Lake so far this season. “We have some logistical difficulties with the Forest Lake targets because of forest fires over there, including one burning right now,” McElroy told Mining Weekly Online.

At a wider level, he stressed that the project was part of a much larger conductive corridor and that the western side of the Athabasca basin remained underexplored, especially compared with the east. “It’s still early days and there’s a lot more to discover.”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation