Dingo reduces downtime with Trakka

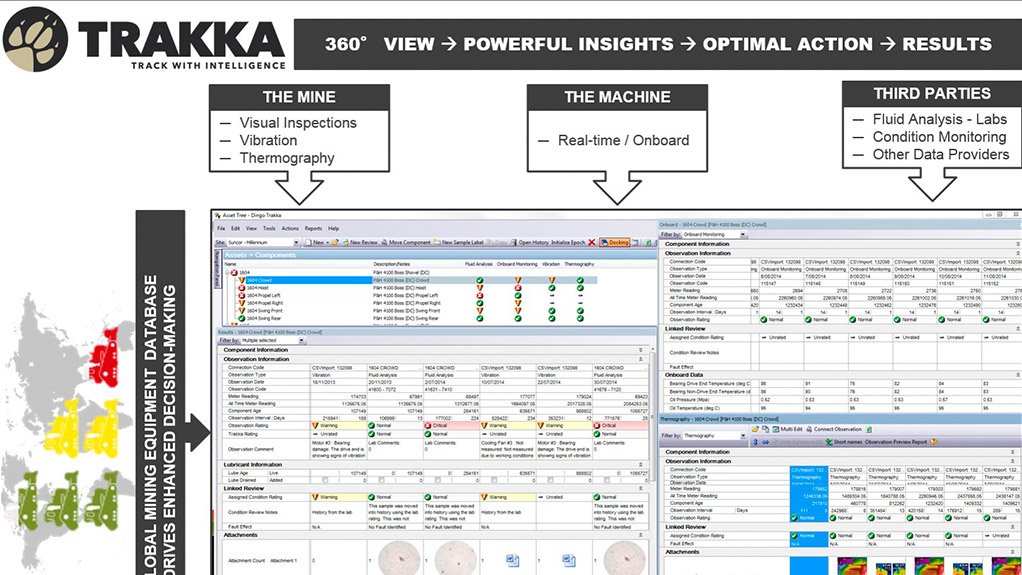

Dingo’s Trakka® Predictive Maintenance software helps maintenance teams reduce operating costs by maximising the life of major components and increasing availability through the reduction of unplanned failures

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Dingo Mining’s Trakka™ Software offers the world’s largest fleet health benchmarking information database. The primary selling point of Trakka is that it helps maintenance teams reduce operating costs by maximising the life of major components and increasing availability through the reduction of unplanned failures.

It provides an easy and cost-effective way to run a predictive maintenance programme with a mine’s existing resources.

A Dingo spokesperson said: “To date, we have saved our customers over US$300 million by helping them implement a systematic approach for managing the health and life of their assets. The use of cloud platforms to monitor equipment performance is not as prevalent in mining as one would expect with today’s technology. Most of the cloud-based based monitoring systems that Dingo interacts with are at the large, well-resourced mines with the latest equipment. Although, we are starting to see some of the more advanced mining companies move towards centralised operating centres, such as IROC at BHP Billiton.”

A key benefit of Trakka is that it provides a platform for any type of mining operation to quickly and cost-effectively migrate to a centralised, cloud-based predictive maintenance system. A number of Dingo customers use Trakka at the regional and enterprise level to help monitor performance and drive improvements across the company.

Trakka manages short and long-term maintenance actions via a comprehensive prioritisation system. Maintenance tasks are created and assigned based on a composite of asset criticality, component health, and alert level severity. Depending on the nature of the identified problem and the importance of the equipment to the operation, corrective maintenance actions are assigned priority levels in order to minimise downtime and optimise component life.

One of the ways Dingo helps customers reduce maintenance costs is by extending the life of components through its Component Life Extension program. “In our experience, most mines are using condition monitoring data to avoid potential short-term equipment failures, but they aren’t focusing on overall component life achievement. The aim of the Component Life Extension program is to optimise the service life of each replaceable component through a structured maintenance management process.

“For example in 2009, a coal mine in British Columbia engaged with Dingo to implement a comprehensive Condition Management program. One of the goals was to reduce maintenance costs by extending the life of their Komatsu 830E and 930E wheel motors, which can which can cost to $200,000 to replace. “When our Condition Intelligence experts saw that the average life of this mine’s GE GDY106 AC wheel motors was only 13,000 hours, based on Dingo’s extensive benchmarking capabilities, they knew that there was a tremendous opportunity for improvement.

Dingo quickly implemented its Component Life Extension program, and in the first year alone, the partnership produced a 67% improvement in wheel motor life, increasing the average life to over 22,000 hours. To date, this operation has saved over $15 million through wheel motor life extension, and is leading the the industry with an average life of 37,000 hours for its most costly Komatsu wheel motors– and operating many of these wheel motors for > 40,000 hours.”

Trakka can be used to improve operational efficiency on any equipment that has condition data. Generally speaking, the highest return is generated by the assets that are the most capital intensive and/or vital to production. While all of Dingo’s customers use Trakka to optimise the performance of their mobile fleets, a significant number have expanded their coverage to mission critical areas such as draglines, longwalls, and processing plants.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation