Concor Opencast Mining Completes 13-Year Project For Impala Platinum

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

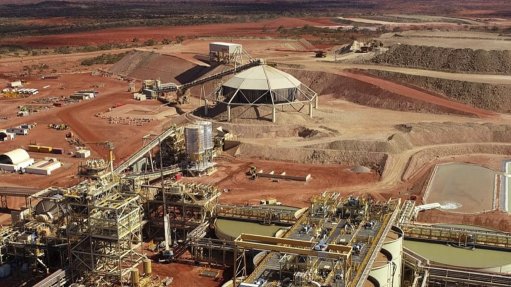

One of the longest-running opencast mining contracts in recent company history has now been completed by Concor Opencast Mining. The Impala Opencast project, located on the Western Limb of the Bushveld Complex near Rustenburg, was awarded in 2002 by Impala Platinum and mining commenced in the vicinity of Impala 6 shaft, with the Concor Opencast Mining team tackling the Merenksy ore body first. In 2005 the team began mining the UG2 ore body.The two Merensky faces were relatively small scale, while the UG2 was present on a much larger scale, with seven faces mined. These reefs ranged over a 9 km area and were mined to a depth of 35 metres. Lower down, the Impala Platinum underground operation mined ore from its shaft systems. The opencast contract included crushing the material to < 300 mm and its delivery to the mine’s stockpile, as well as rehabilitation of mined areas.

Since 2002 the contact was renewed on an annual basis until all opencast resources were depleted. Between November 2009 and December 2013 Concor Opencast Mining mined 49 340 574 bm3 of blasted overburden, 6 576 454 bm3 of topsoil and 8 871 767 tons of reef.

“This project was tightly controlled throughout its duration to mitigate the associated challenges,” Roger Hearne, acting general manager of Concor Opencast Mining, says. “For example, mining took place in close proximity to both mine infrastructure and housing occupied by members of the local community. Great care had to be taken not to impact these structures and we achieved this by keeping the vibration from blasting to a minimum. In addition, blasting was only carried out twice a week out of consideration for the local communities.

“At all times we also had to be careful not to hole through to the mine’s underground workings. For this, we depended on existing surveys and worked closely with the mine surveyor to ensure that highwall positions were correct.” At the end of the project, the team had achieved more than five million fatality free hours — 1 196 LTI-free days, earning several Impala Platinum and Concor Opencast Mining safety awards along the way.

Hearne says this remarkable achievement can be attributed to the Murray & Roberts’ STOP.THINK.ACT 24/7 safety programme together with the Bill of Rights and Life saving rules. Weekly safety audits were carried out by Concor Opencast Mining, while Impala Platinum undertook 40 day safety audits. Visible felt leadership was also part of the safety environment, aimed at influencing and transforming behaviour.

A total of 240 people worked on the project site, which spanned an area of 15 km. Equipment comprised five bulk excavators for overburden removal; six smaller excavators for cleaning the ore body and extraction of the ore body; five dozers for moving overburden and top soil; 25 trucks on site; three water carts and various ancillary support plant. A static jaw crusher serviced the southern pits during the project, while a mobile jaw crusher serviced the northern pits.

Concor Opencast Mining applied the strip mining method, with average advances of 30 metres wide. The team was also responsible for the complete drilling and blasting operation in all pits. The ore body was exposed, extracted and transported to a rail siding 5 km away, where it was crushed and transported by rail to the plant for further processing. Haul road maintenance was critical to minimise wear and tear on vehicles and ensure safety.

Throughout the project Concor Opencast Mining maintained an active presence in the mine’s local communities. The Concor Orphan Project was introduced in 2008, revolving primarily around the delivery of food parcels to the three primary schools closest to the project site. The company also employed a local emerging sub-contracting company, which it mentored to successfully undertake the required top soil rehabilitation. Personnel were trained in production methodology, on how to achieve targets, on costing and on safety issues.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation