Coal mining needs effective extraction means

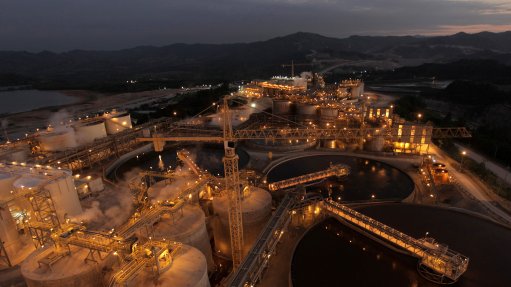

LONGWALL COAL MINING A longwall miner used to extract coal in underground coal mining allows for a higher extraction rate of coal

The best process for extraction of coal depends on the geographical and geotechnical information of the deposit, says Johannesburg-based multidisciplinary engineering consulting company GO Holistic Engineering engineering consultant Kevin Jacobs.

He tells Mining Weekly that South Africa’s diverse coal mining operations require different methods of effective extraction, which depend on the depth of the coal deposits.

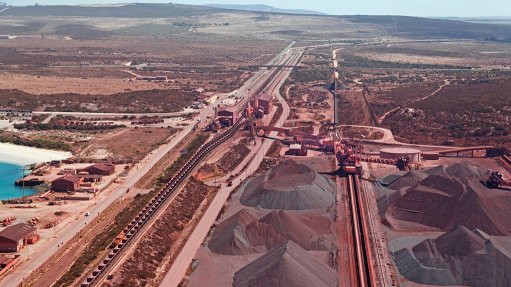

Opencast mines – the more common type of coal mining in South Africa – require blasting to extract coal, after which draglines are used to recover the coal onto stockpiles, Jacobs explains.

Meanwhile, key advantages of using longwall and continuous miners in underground coal mining include using those which have a high level of automation.

“Longwall miners are completely automated pieces of equipment requiring a driver to control the starting and stopping of the shearer and monitor the cutting process,” Jacobs says.

He explains that a longwall miner used underground is an extremely complex and automated piece of equipment that allows for a higher extraction rate of coal, but requires an advanced skills set to be operated efficiently.

It mines along a coal seam using a shearer, with the seam supported by hydraulically operated chocks. “As the shearer cuts into the coal seam, the chocks move forward to align the conveyor system with the shearer to collect the falling coal and extract it onto the main conveyor.”

A continuous miner, however, mines into a coal seam directly, with the coal falling directly onto a conveyor while the miner moves forward along the coal interface.

Jacobs nevertheless reiterates that underground coal mining is a specialised undertaking with inherent dangers. “The combined effects of explosive gases in a confined space within close proximity of electrical, control and communication interfaces, along with high-pressured hydraulics to support and drive the equipment, makes it an extremely sensitive and dangerous working environment.”

Service Offering

Jacobs stresses that GO Holistic Engineering has experience in longwall applications, working with original-equipment manufacturer (OEM) companies that provide services for the underground coal mining industry.

The GO Holistic Engineering team has worked on various projects in Australia, dealing with OEM companies supplying the mechanical and electrical equipment required to commission longwall mining operations. The team also works with mechanical, electrical, control, communications, gas-detection and protection systems at mine sites.

The company offers a range of consulting services for the industry, which include the development of business strategies, designing high-quality and scalable solutions, and building brand experiences through partnerships.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation