Boring to depth

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

By Simon Anderssen - Associate Portfolio Manager, Kagiso Asset Management

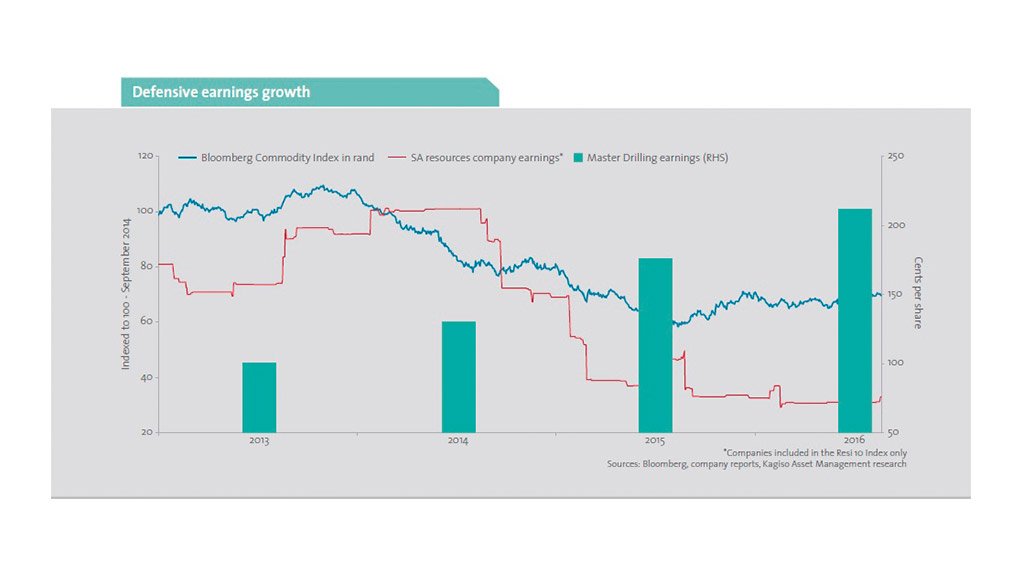

Mining services companies are often tarred with the same attributes as their customers: significant commodity price risk and highly cyclical earnings. Yet there are a handful of service providers that are able to generate a stable earnings stream during the most challenging commodity cycles. We consider Master Drilling one of these few.

Master Drilling is a global drilling solutions business specialising in raise bore drilling. It listed on the JSE Securities Exchange in December 2012 and raised R430 million. The capital has been employed to expand capacity by designing and building new raise boring machines.

Over the last four years, the company has delivered consistent earnings growth during one of the most severe commodity downturns, in which aggregate earnings of the JSE resources companies declined 70%. This defensiveness is evidence of a robust demand for the company’s drilling, its diversification and the financial health of its clients.

Raise boring explained

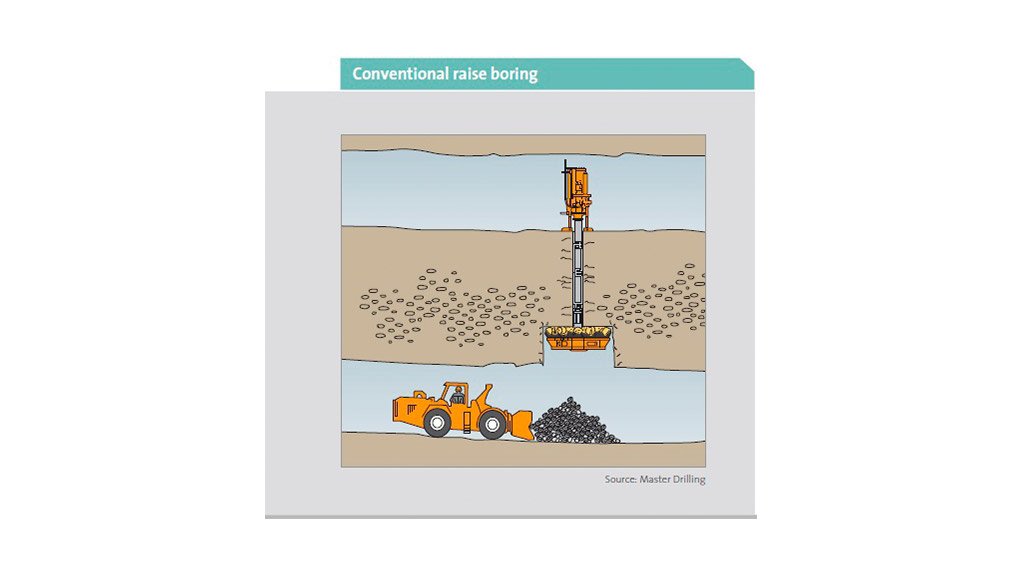

Master Drilling generates 80% of its revenue from raise boring, a method of mechanically boring a shaft between two levels. It first entails sinking a pilot hole approximately 350 millimetres wide from the upper to lower levels. Once through, the pilot hole is reamed to a larger size by attaching a reamer head to the end of the drill rods and mechanically pulling and turning this reamer head to the surface. Debris and rock falls to the lower level, and is removed using existing infrastructure. The reamed shaft can be as deep as 1 000 metres and up to 4.5 metres in diameter.

Raise boring is used in mining for ventilation shafts, ore passes or access shafts ; in civil construction for underground tunnelling, commuter metro rail networks or infrastructure projects; and in hydro-electric plants for pressure shafts. Master Drilling is active in each area but the majority of its exposure is to mining. The company competes directly with a number of regional players.

Raise bore drilling has multiple advantages over the alternative approach of blast sinking using explosives. Since the machinery does most of the work, raise boring is less labour-intensive and improves safety as it removes personnel from the unstable rock face. Its financial advantages are also compelling: a raise bored shaft can be completed in approximately half the time and at a

30% to 40% saving versus conventional methods for sinking a comparable shaft.

A global footprint

Mining is an extractive process and requires underground infrastructure to be continuously developed further away from existing shafts to sustain output levels. Therefore, stay-in-business spending on infrastructure, such as ventilation shafts and ore passes where raise bore drilling is utilised, is a relatively stable element of total mining capital expenditure. This is a fundamental reason for Master Drilling’s steady earnings delivery.

The group’s origins and headquarters, in the unassuming town of Fochville, an hour’s drive south-west of Johannesburg, belie a global footprint and a diversified commodity basket.

In 2016, South Africa accounted for just 25% of group revenue and other African projects another 20%. The remainder of revenue was primarily generated in Latin America, particularly Brazil, Chile, Columbia and Mexico. The group actively seeks dollar-denominated contracts in most geographies but accepts local currency risk in regions where the quality of the counterparty or size of the project mitigate this risk. Operating costs are predominantly paid in local currency.

The company has been able to expand geographically on a project-by-project basis by shipping its raise boring machines - which can weigh up to 110 tonnes - in containers and assembling on site. The fleet’s mobility allows the company to redeploy assets in line with demand changes, and maintain high utilisation levels and operating margins.

Diversification by type of commodity further reduces operational and commodity risk. Projects at gold mines across multiple countries account for a third of revenue. Copper, concentrated in Chile, and polymetalic (lead/zinc/silver) mining projects each contribute a quarter.

Innovation drives automation

Safety and cost considerations will direct the global mining industry towards greater automation and mechanisation in the future. Master Drilling’s innovative track record and project experience suggest it is well positioned to contribute to, and benefit from, this transition.

The company’s achievements include, respectively, the world’s widest, deepest and most accurate raise-bored holes, highlighting its ability to extend the boundaries of raise boring. This is accomplished through constant innovation and re-design of equipment throughout the drilling process. Over many years the company has developed the capabilities to design its own machines, drill rods and cutters for project-specific conditions. This gives Master Drilling structural advantages on costs and shorter lead times for equipment compared to its competitors.

The company’s pursuit of incremental efficiency improvements includes an automated drill-rod handler that loads and unloads drill rods, and an automated drilling control system. The latter allows raise boring machines to operate uninterrupted for a short period during operator shift changes that coincide with mandatory evacuation of all on-mine personnel during blasting, when noxious gases are released. The company aims to maximise the automated operating times over a 24-hour cycle and thereby reduce personnel functions and interventions.

Further examples of its internally-developed technology include remote operated shaft inspection and support systems and a gripper machine that is designed to bore diagonally. The gripper is being trialled at a South African gold mine.

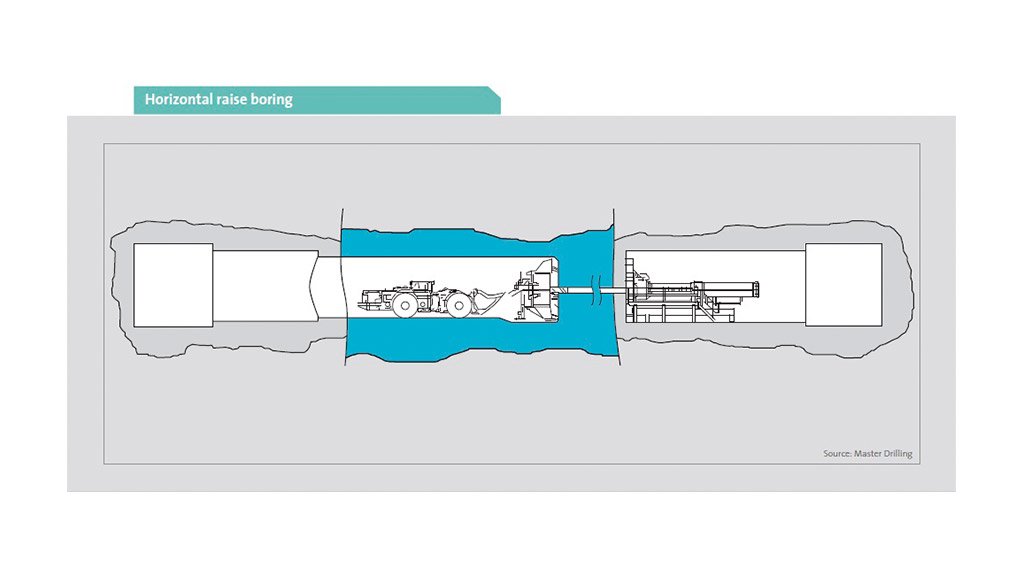

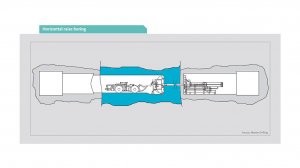

Raise boring laid flat

In recent years Master Drilling has experimented with a horizontal application of raise boring and has announced the successful completion of a trial at an SA diamond mine. The trial saw them drill a 180-metre-long tunnel, 4.5 metres in diameter, through very challenging Kimberlite.

The term horizontal raise boring (HRB) oversimplifies the engineering feat. Boring horizontally requires counterbalancing the downward gravitational pull of the reamer on the raise boring equipment, up to 180 metres away, to ensure the tunnel is level. A further challenge was debris removal from the reamer head. In a vertical application, this falls away with gravity. In this project, water could not be used for flushing, because it would compromise the stability of the surrounding Kimberlite, and a suction system had to be developed to remove debris.

The advantage of HRB machinery over traditional tunnel boring machinery is that it can be disassembled into smaller components, making it easier to transport within existing mining infrastructure.

The opportunity for HRB could be immense. At most underground mines, for every metre of vertical shaft sinking, there are approximately three to four meters of horizontal tunnels developed to transport personnel, equipment and ore. We expect HRB to be an appropriate method for some of these tunnels, which could materially increase the scope for Master Drilling’s services. It is too early to include this new business opportunity into our expectations for the company but we will closely follow HRB’s commercial acceptance and re-evaluate if necessary.

Boring blind

Master Drilling’s ambitions extend further: it has announced plans to develop a blind shaft boring system that does not require access from the bottom level. This would effectively enable shaft sinking using mechanised boring instead of traditional blast sinking with explosives. As with raise boring, there would be substantial time and cost savings in accessing the orebody this way. It would improve the value of new projects, perhaps even making previously unviable projects profitable.

The company is patenting a system to sink an access shaft 1 200 metres deep and eight metres wide, capable of carrying personnel and equipment. This project is a number of years away from being proven, but could be a game-changer for the mining industry in terms of efficiency gains.

Nothing boring about the return to shareholders

The share price has more than doubled since listing as the company has steadily grown earnings. Looking forward, we expect the group’s free cash flow to improve significantly as its expansion phase draws to an end. This will reveal the strong cash generative qualities of the business model and provide management with the resources to pursue its HRB or blind-boring projects that will sustain growth in the future. Early evidence of this emerging free cash flow was the declaration of a maiden dividend in March 2016.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation