Johnson Controls sells two more chillers to copper miner

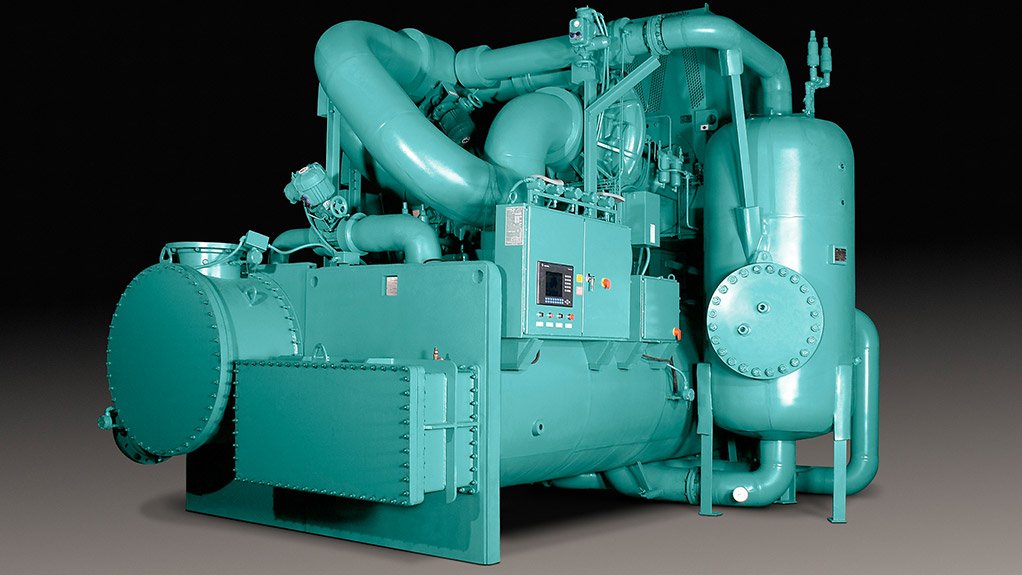

YORK CYK CENTRIFUGAL CHILLER The new chillers will assist in improving ventilation and cooling at Palabora’s mine thereby facilitating the expansion of its operations

RUSSEL HATTINGH The CYK chillers are designed using two centrifugal compressors arranged in series to handle conditions outside the range of typical centrifugal chillers

Photo by Duane Daws

Technology group Johnson Controls has sold refined copper producer Palabora Mining Company’s subsidiary, Palabora Copper, two more 3 500 kW York CYK compound centrifugal chillers.

The next two chillers will be assembled and commissioned in early 2016 by a Johnson Controls team, with a Palabora Copper team taking over the maintenance of the systems.

The latest purchase forms part of the company’s R9.3-billion Lift II project, in Limpopo, which aims to increase the depth of the mine to 1 600 m. This is an initiative that started in 2012 and will extend the life of the mine to 2030.

Johnson Controls states that the new chillers will assist in improving ventilation and cooling at the mine thereby facilitating the expansion of the company’s operations.

“As of February this year, we are working 450 m below the 1 200 m lift where the first two CYK chillers were installed in 2013 and 2014 respectively. These next two chillers will also be installed at 1 200 m, providing us with the cooling capacity we need to safely develop and mine the new level,” says Palabora Copper ventilation, cooling and water handling manager Gavin Meredith.

He says that the first chiller has been operational for “just over a year” and has “performed well”, while the second is scheduled to be commissioned in July this year.

Johnson Controls points out that the CYK chiller installation at the Palabora mine is the first of its kind in Africa, and the first underground installation globally.

“By installing the chillers underground, the mine reduces the need to pump water to the surface for cooling. Upcast air is used to reject heat in underground cooling towers and cool air is blown down to the work face from 1 200 m,” the technology group explains.

Further, Meredith avers that Palabora Copper is a “pioneer” in terms of copper mining, because of the depth at which it is mining and owing to the hard rock block cave mining method that it is using.

“The composition of the rock is unusually hard for this type of mining, which impacts operations and conditions underground. Our ventilation and cooling strategy – and the performance of the chillers – is instrumental in allowing us to achieve safe development of the mine at this depth. To date, the performance of the chillers has been above faceplate specification,” he highlights.

Meredith says that the CYK chiller technology was a key deciding factor for Palabora Copper in its selection of a solution.

“At 1 650 m, 50 m deeper than initially targeted, virgin rock temperatures in the mine are 52 °C. This environment requires chillers to operate beyond the limits found in typical air-conditioning applications.”

Johnson Controls engineered systems branch manager Russell Hattingh says that the CYK water-cooled centrifugal chillers are designed using two centrifugal compressors arranged in series to handle conditions outside the range of typical centrifugal chillers.

“Extreme conditions are characterised by leaving chilled fluid temperatures below 2 °C, leaving condensing fluid temperatures above 41 °C, or a combination of both.

“When the leaving chilled fluid or leaving condenser fluid temperature exceeds standard limits, the lift on the compressor increases dramatically. The compressor must develop higher differential pressure on the refrigerant gas in the compression phase, which results in higher head pressure,” he explains.

Hattingh highlights that the CYK chiller overcomes these compressor-design challenges by using the principle of compounding.

“A compound design arranges two individual compressors in series. By flowing the refrigerant gas through two compressors, the pressure ratio becomes the sum of the two individual centrifugal compression ratios. The result is a much higher total lift pressure available to the system, which is able to handle the high head demanded by extreme conditions,” he says.

Moreover, Meredith points out that Johnson Controls was the only company that could offer Palabora Copper a high head, high capacity, industrial type machine fit for the mining environment with additional customised features, such as specialised programmable logic controller technology that integrated with the company’s supervisory control and data acquisition system.

“This will provide us with the necessary 14 MW capacity we need. A fifth chiller, which is likely to be ordered at the end of 2016 and installed in early 2017, will provide failover capacity, thereby completing the installation process,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation